Energy Recovery, Inc.

Energy Recovery, Inc. - Energy Recovery Technology

Energy Recovery (Nasdaq: ERII) is a trusted global leader in energy efficiency technology for the water treatment industry. Building on our pressure exchanger technology platform, we design and manufacture reliable, high-performance solutions that generate cost savings, increase energy efficiency, and reduce carbon emissions across several industries.

STAND NUMBER:

12.500

CATEGORIES:

Products and services

Water Treatment:

Filters, Filtration other, Purification Plants, Water supply and water management, Desalination equipment, Membrane filtration

Wastewater:

Filters, Filtration other, Purification Plants, Water supply and water management

EVENT:

Aquatech Amsterdam 2025

ADDRESS:

1717 Doolittle Drive 94577 San Leandro CA United States

WEBSITE:

Products

News

Downloads

Reliability & Design Life of PX Pressure Exchanger

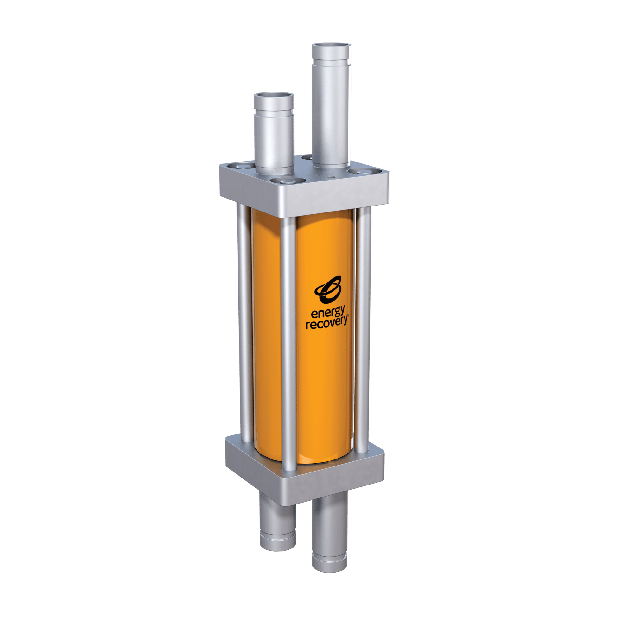

PX® Pressure Exchanger® (PX) energy recovery devices (ERDs) manufactured by Energy Recovery, Inc. are designed and built for long-term reliability and safe performance.

PX Q400: Highly Efficient Energy Recovery Device

Energy Recovery is the market leader for energy-saving technology in the seawater reverse osmosis (SWRO) desalination industry. The company’s flagship technology is the PX® Pressure Exchanger®, an isobaric energy recovery device (ERD) that reduces energy consumption by up to 60% in desalination applications.

Low-Pressure PX for Sustainable Agriculture

Agrícola Don Ricardo selected ReliX Water, a leading water treatment system provider for the agricultural sector, to design a modern, high-recovery BWRO treatment plant that met sustainability standards while producing high-quality water. Focused on energy-saving technology, ReliX Water chose Energy Recovery’s low-pressure PX® Pressure Exchanger® (LP PX) to reduce the energy consumption and associated emissions of the BWRO system, integrating one PX L140 in the double-stage design.

Mexico Brewery Case Study

Plant designers chose to integrate Energy Recovery’s turbocharger to lower the system’s energy consumption and optimize flux across the first and second stages. The brewery collaborated with a leading membrane supplier and Energy Recovery, Inc. to design its reuse system. This innovative wastewater treatment plant was optimized using computational fluid dynamics, utilizing highly selective membranes and Energy Recovery’s efficient turbocharger – a cost-effective solution.

Hilton Plaza Case Study

Resorts and hotels by the Red Sea in Egypt depend on seawater desalination to provide a reliable and energy-efficient source of clean, potable water. The EPC contractor decided to utilize a proven solution they already had on hand, Energy Recovery’s PX Q300, to ensure seamless integration and plant uptime.

ATACAMA Case Study

In 2021, the joint venture comprised of the companies GS Inima Environment SAU and Constructora Claro Vicuña Valenzuela led the construction of one of the largest desalination plants in the region. Its large capacity required energy optimization to reduce operational costs. GS Inima partnered with Energy Recovery to install its proven and reliable pressure exchangers, one of the solutions to lower operational energy costs and increase efficiency.

Ranitec Tannery Case Study

Ranitec CETP was able to save energy and costs needed for reverse osmosis systems by partnering with Energy Recovery. The plant chose to incorporate a full suite of product solutions, including the turbocharger, PX® Pressure Exchanger® energy recovery device (ERD), Aquabold high-pressure pump, and circulation pumps.

ACWA CASE STUDY

As one of the biggest seawater reverse osmosis (SWRO) desalination facilities in the world, ACWA Power Rabigh 3 IWP was designed to address the growing demand for water while also keeping energy consumption low.

Energy Recovery’s PX devices were a key component in achieving the stated goal and, on an annual basis, will save ACWA Power Rabigh 3 IWP approximately 500 GWh each year.

ENERGY RECOVERY Sinochem Case Study

Sinochem International and an innovative enterprise focusing on membrane product

solutions for the water treatment industry, to design a treatment facility, using a combination of technologies to pretreat the waste stream. By employing two reverse osmosis (RO) stages and an ultra high-pressure reverse osmosis (UHPRO) stage, Sinochem reduced the process flow rate by 90%, before using a thermal process on the remaining flow to reach zero liquid discharge (ZLD).