Products

Specialty and Dairy

Spiral-wound and Heat-sanitizable Membranes

for dairy and specialty separations. Toray manufactures membrane elements in sanitary designs and for heat-sanitizable applications at Toray Membrane USA (TMUS) in San Diego, California. We specialize in reverse osmosis (RO), nanofiltration (NF), ultrafiltration (UF), and microfiltration (MF) for various separation needs in dairy, food & beverage, pharmaceutical, and industrial processes. Toray has a team of product specialists ready to develop custom engineered solutions for your specific need.

Toray RO/NF/CSM™

RO/NF Membrane Elements

for production of potable water. CSM products, manufactured by Toray Advanced Materials Korea Inc., are innovative and cost-effective reverse osmosis, nanofiltration membranes serving the municipal, industrial and residential markets. The goal of CSM is to achieve thorough customer satisfaction in the filtration and separation industry. Supported by a global network we are committed to ensuring better quality, reliable technical support, competitive prices and responsive delivery time for our customers.

Toray RO

High-performance RO Membrane Elements

that feature durable membrane chemistries for reliable and efficient operation. TORAY began producing spiral-wound reverse osmosis and nanofiltration membrane elements in 1968, first using cellulose acetate membrane material. Today, our product line includes a full range of state-of-the-art cross-linked polyamide composite membranes manufactured under ISO-9001 certification for consistency in product and service quality.

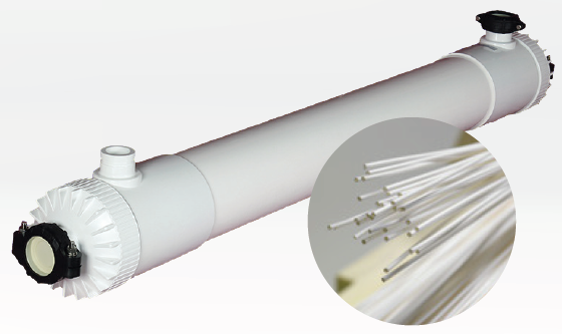

Toray UF

Hollow-fiber PVDF UF Membranes

with a 0.01 µm nominal pore size boast one of the industry’s strongest fibers. Toray's PVDF (Polyvinylidene fluoride) hollow fiber UF membrane module has one of the industry's highest mechanical strength and chemical resistance (oxidation, pH), and effectively removes suspended solids and microorganisms such as pathogens for various water purification applications. Our innovative membrane module is a product of more than 30 years of polymer science and membrane fabrication technologies at Toray Industries,

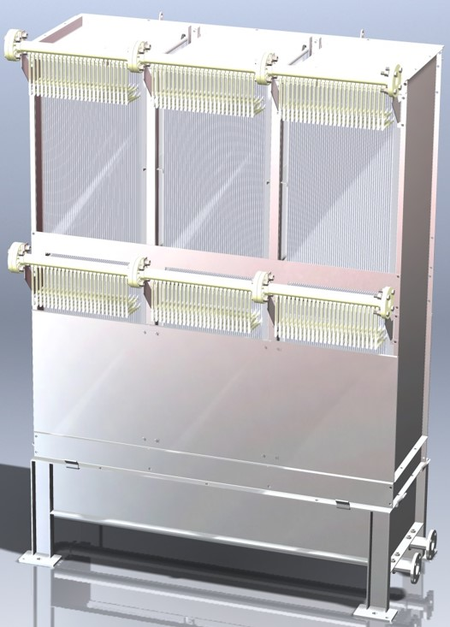

Toray MBR

Flat-sheet PVDF MBR

handles high suspended solids loading and produces high-quality effluent. MBR (Membrane Bioreactor) process is a combination of biological wastewater treatment and filtration. Biodegradable pollutants are reduced using bacteria and microorganisms. Following biological treatment, activated sludge is separated from the treated water by Toray's PVDF flat-sheet membrane with a nominal pore size of 0.08 microns densely distributed along the membrane surface.

RPI Antiscalants

ROPUR RPI® Antiscalants for RO system

ROPUR RPI® Antiscalants are designed to optimize RO plant performances while saving money through optimizing plant recovery/conversion rate, protecting membrane surfaces from erosion and oxidation damages, minimizing the bio-fouling recurrence, adapting the packaging for an Easy and Safe site handling. ROPUR RPI® Antiscalants comply with today’s water treatment requirements, including NSF 60, country-specific government drinking-water certificates and ISO 9001/14001 production certification.