Turning the tide against PFAS: Two further technological advancements

Two notable technological innovations have surfaced, offering promising strides in the battle against PFAS synthetic chemicals, widely used in various industrial and commercial applications.

Biosolid PFAS destruction process

Heartland Water Technology, headquartered in Hudson, Massachusetts says its new biosolids destruction process delivers significant volume reduction while simultaneously addressing the issue of PFAS contamination.

The process involves LTC Dry, a recirculating thermal drying technology that employs conductive heat to process wet waste material (typically dewatered sludge) with minimal emissions. The Dryer's thermodynamic process utilises dry matter for economic and reliable heat transfer.

Heartland said it’s capable of processing up to 50 tonnes per day of biosolids with moisture content ranging from five per cent to 35 per cent. This then dramatically reduces volume by up to 95 per cent. The dried material is then channeled into a HelioStorm gasification process where it is processed at temperatures up to 10,000°C, completely destroying all PFAS compounds while attaining over 90 per cent carbon conversion, it claimed.

The challenges with PFAS

The US Geological Survey predicts that at least 45 per cent of tap water could have one or more PFAS in it.

Despite their extensive use in various consumer and industrial products, the robust chemical properties of PFAS render them resistant to degradation, leading to their accumulation in the environment causing potential long-term health risks.

Studies have linked exposure to PFAS with a range of adverse health outcomes, including potential disruptions to the endocrine system, compromised immune function, and increased risk of certain cancers. Additionally, the persistence of PFAS in the environment poses a threat to ecosystems, with potential impacts on wildlife and aquatic life.

As these chemicals continue to be detected in water sources, food products and even household items, the need to understand and address the potential consequences of PFAS exposure remains a critical area of concern for public health and environmental protection efforts worldwide.

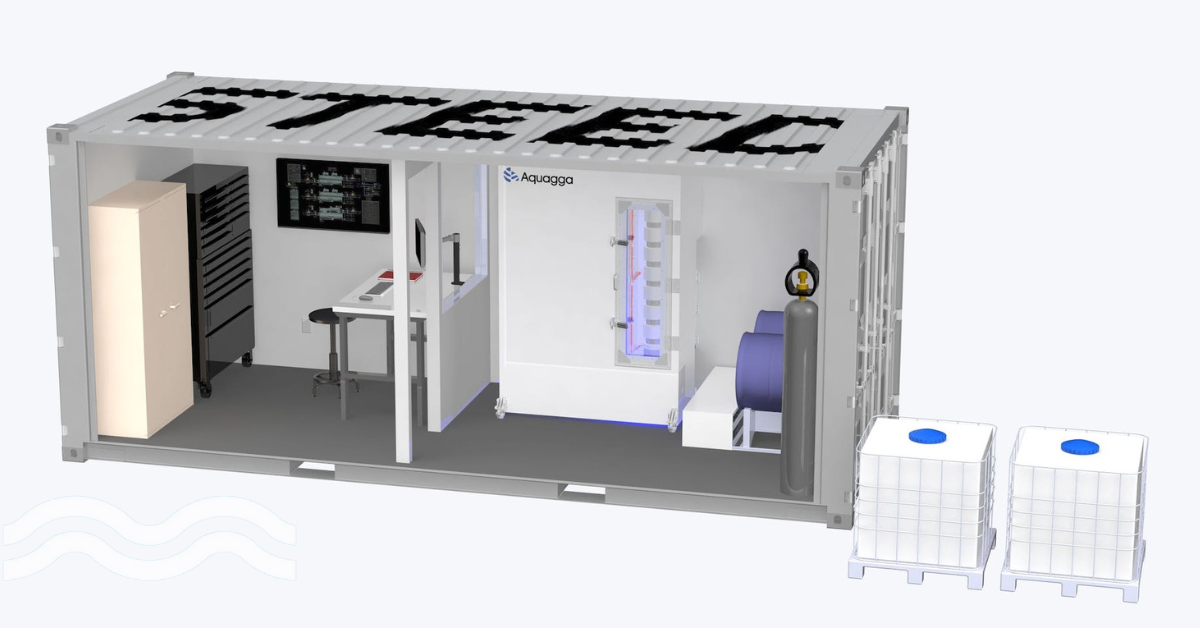

PFAS destruction units from freight containers

Meanwhile, Aquagga, a startup based in Tacoma, Washington, is also working to destroy PFAS with its "PFAS Destruction Unit", a portable system housed within a small freight container. The company, which recently received $7 million in funding, said its unit dismantles 99 per cent of the persistent PFAS chemicals from water.

The system uses hydrothermal alkaline treatment operating at 570 degrees Fahrenheit and approximately 25 megapascals of pressure, creating a caustic environment by adding caustic soda to break down the molecular bonds of PFAS.

Alaska’s Fairbanks International Airport recently used the system to treat 20,000 gallons of water contaminated by PFAS-heavy firefighting foam, also called AFFF. The PFAS Destruction Unit successfully reduced the pool down to 1,000 gallons of foam, the company said.

We promise never to send you spam and you can unsubscribe at any time!