TECH DIVE: The dawn of 3D printing membrane spacers

3D printing has come a long way from producing small plastic whistles on your desktop in eight hours.

Now, 3D printing is revolutionising almost every sector, offering precision design and the creation of complex components.

Indeed, the water sector is no different as 3D printing looks set to disrupt the membrane market.

Being able to print bespoke membranes with unparalleled accuracy, unique materials and on a micro-scale, 3D printing opens the door for levels of efficiency that once were not thought possible.

But what is the scope of 3D printing membranes in the water sector? How does it work? And who are the key players to follow?

In our latest Tech Dive, Aquatech Online takes a look at 3D printing membranes and separators:

What is 3D printing?

3D printing is the process of producing a three-dimensional object from a digital file.

Sometimes referred to as additive manufacturing, an object is created by laying down successive layers of material until the object is created, meaning that each layer represents a cross-section of the object.

Source: Unsplash

3D printing allows you to produce intricate shapes and components using less material than traditional manufacturing methods.

It was in 1981 when Dr Hideo Kodama created one of the first rapid prototyping machines that created parts layer by layer, using a resin that could be polymerized by ultraviolet (UV) light.

But it was not until 1986, that the first patent for stereolithography (SLA) was filed by Chuck Hull, who is widely considered the inventor of 3D printing.

A brief history of 3D printing

Much of the 90s saw rapid growth for 3D printing with numerous companies experimenting with different materials and technologies, but it wasn't until 2006 that the first commercially available selective laser sintering (SLS) printer was available.

However, it was the RepRap project in 2005 that would have the biggest impact on the growth and adoption of 3D printing.

The RepRap project was founded by Dr Adrian Bowyer, with the goal of the project to re-think additive manufacturing as a low-cost technology capable of self-replication.

As a result, the first low-cost 3D printer called the RepRap was born and with it the first opened source 3D printing technology.

In recent years, 3D has become an almost indispensable tool for practically every industry - for example in 2018, the International Space Station printed the first tool in space, using a low-gravity 3D printer.

3D printing is being used to create; furniture, glasses frames, prosthetics, dental fillings, scale models for architecture, film props and even used to replicate ancient artefacts and fossils, and... membrane spacers.

What is a 3D-printed membrane spacer?

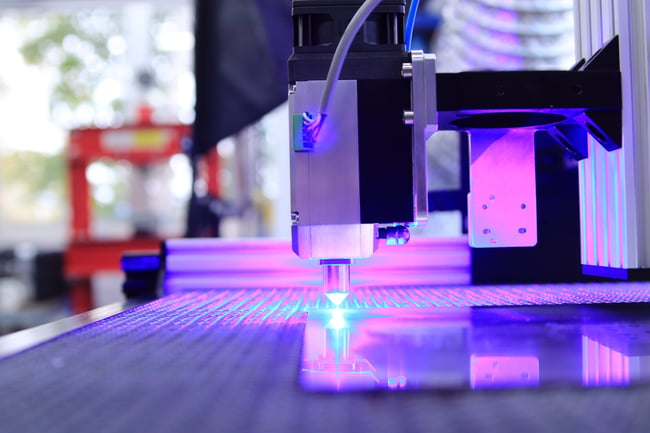

Membrane spacers are used in spiral wound reverse osmosis (RO) membrane modules to keep the membrane sheets apart as well as to enhance mixing.

Spacers are also used to help mitigate membrane fouling by creating turbulence over the feedwater flow.

With the dawn of 3D printing, it has enabled companies to produce feed spacers with complex geometry as well as maintain high accuracy.

A 2023 paper published in the Journal of Environmental Chemical Engineering, looked at the potential of 3D-printed feed spacers in reducing the environmental footprint of membrane separation processes.

Source: Journal of Environmental Chemical Engineering

It found that in the last few years advancements in 3D printing technologies have led to faster and higher precision printers with microscale resolution (>1 µm).

The paper went on to argue that novel feed spacers are capable of enhancing mass transfer, reducing feed channel pressure (FCP) drop, and minimizing biofouling became now possible. I also found that some spacers can potentially reduce the energy consumption of the filtration process, which in turn reduces their environmental footprint.

However, the paper did note that 3D printing material toxicity and higher fabrication energy requirements are still environmentally concerning but concluded that should this be overcome 3D-printed spacers will replace the commercially available spacers and be entirely accepted for large-scale manufacturing.

Who are the key players?

Despite the technology being fairly new to the sector, already we are starting to see the key players start to emerge.

Aqua Membranes

Across the pond in the US, start-up company Aqua Membranes started out when the company's founder, Rodney Harrington, experimented in his garage with creating RO elements using 3D printed technology.

Since then, Aqua Membranes has continued to build on his idea but creating a custom-designed large-format printer that Aqua Membranes CEO, Craig Beckham, says allows them to put its patterns down on the membrane surface which he calls the heart of its innovation allowing them to lower energy and water waste in the water sector.

Source: Aqua Membranes

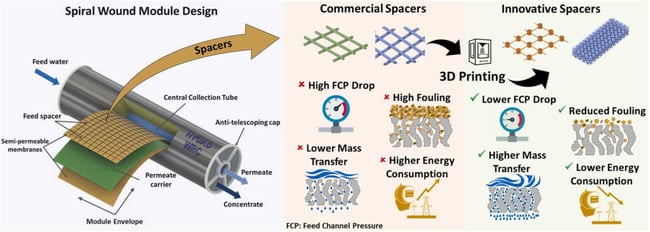

As opposed to using the traditional mesh spacers, Aqua Membranes developed its own patented 3D spacers called the ConZerv.

Whereas mesh acts like a dam in a river blocking the water and slowing it down, Aqua Membranes says its ConZerv printed spacers act more like boulders in a river still slowing down water, but it is easier for water to keep velocity.

The start-up says the ConZerv can reduce energy waste by cutting pressure drop by up to 60 per cent enabling savings in the cost of operation and greenhouse gas emissions.

Aqua Membranes offers the elements in both 4040 and 8040 sizes to fit both high and low-output systems.

Back in 2021, US semiconductor manufacturing company, Micron, announced its financial backing of the company.

Micron plans to launch a pilot program using Aqua Membranes’ technology at its Boise site in Idaho. If successful, this programme could be expanded to sites around the world, the company said.

“Aqua Membranes’ reverse osmosis innovation could be an elegant and cost-effective way to improve on equipment already operating in Micron fabs while increasing water reuse,” said Marshall Chase, director of sustainability at Micron. “This is problem-solving through innovation.”

Evove

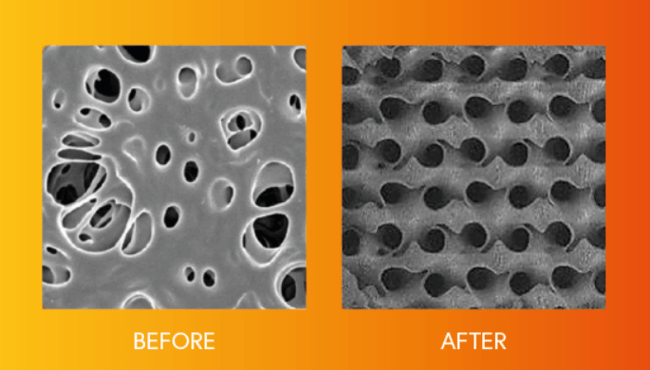

UK-based company Evove, formerly G2O Water Technologies, has been making a lot of noise in the 3D printing space.

Source: Evove

Its patented Separonics™ says is a precisely engineered 3D printed filtration and separation technology that provides a physical barrier that can be designed bespoke for any application or customer.

By definition, a separonic is a transforming membrane that can recycle water and recover valuable resources at a reduced price point.

Spacers sit above the membrane so that when it’s rolled into a spiral, they separate the layers, providing a cavity for the liquid to flow.

In this context, 3D printing is not referring to a small device that sits on a desk and takes two days to print a whistle. Instead, it will be 3D, industrial printing at scale.

Evove is 3D-printing its spacers to create unique shapes using computational fluid dynamics to model flow through the membrane to optimise spacer design.

Speaking to Aquatech Online, Chris Wyres, CEO of Evove says "We will be able to print at full scale, eight-inch wide, 1.8 metres long, whatever length really, it doesn't matter."

"The key is that we will be able to print features and structures which conventional manufacturing can’t and using high-performance computing and AI to optimise those designs for specific applications."

At the end of 2021, the company signed a Joint Development Agreement with Meta Additive to produce an advanced additive manufacturing solution to 3D print its ceramic Separonic membranes, with plans to deploy in 2023.

As of January 2023, Evove signed a memorandum of understanding with the Saline Water Conversion Corporation, one of the world's largest desalination companies.

As part of the deal, the UK-headquartered company will provide enhanced coated membranes and 3D spacers that will be tested in a desalination plant in the Gulf to reduce energy consumption in the reverse osmosis process.

Nanosun

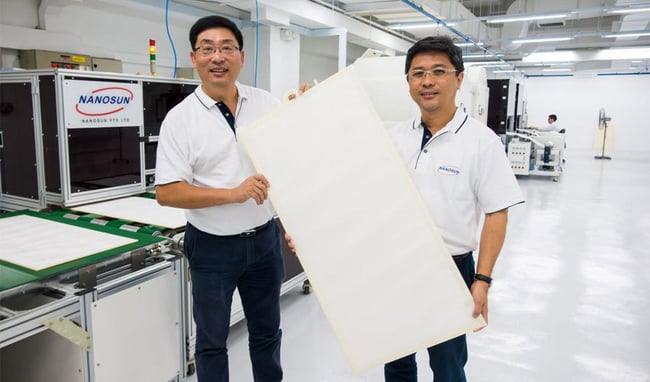

Continuing around the globe, Singapore-based membrane manufacturing start-up, Nanosun, has created a 3D-printing facility to manufacture water treatment membranes.

A spin-off from Nanyang Technological University (NTU), Nanosun uses additive manufacturing to create membranes that it claims are five times more efficient than the traditional process, which uses polymer and ceramic-based membranes.

Source: Nanosun

The company has developed its 3D-printed membranes to be used in desalination, industrial wastewater management and municipal wastewater management.

Already the start-up has worked within its borders with a large semiconductor manufacturer and crossed to China to supply its 3D printed membranes in a municipal wastewater treatment plant with a capacity of 20 million litres a day.

Nanosun recently announced it had secured a 6000 m3/d water reclamation deal and a 1440 m3/d RO system improvement project for ammonia and fluoride removal with a US-based semi-conductor manufacturer.

Co-founded by NTU Associate Professor Darren Sun, and Wong Ann Chai, the company says it is looking to the next step after its technology was validated in Singapore.

Speaking on Nanosun's future, Mr Wong said: “We need to able to provide the most cost-effective solution for our next phase of growth.

"The international market demand for industrial wastewater treatment is going strong since most countries do not want to pollute their scarce surface water and underground water resources."

Nanosun says approximately $6 million has been invested to open its new 3D printing factory.

New technology, the same barriers?

Anyone familiar with membranes knows how long it can take for an innovation to be fully adopted by the water sector.

Ceramic membranes have been knocking at the door of the water sector for the last decade, but it is only now that ceramic membranes have started to enter the utility market.

Its predecessor, polymeric membranes, also faced similar headwinds to ceramics, with the uncertainty anchored towards questions on robustness, compared to cost.

But will 3D-printed separators and membranes face similar challenges trying to work with municipalities?

Beyond 3D printing membranes and spacers

3D printing has been around for over 40 years but in the last decade, it has seen exponential growth.

Its tools and capabilities seem practically limitless so much so that the 3D printing market is predicted to be worth $20 billion by 2026, according to industrial 3D printing consultancy specialist, AMPOWER.

The next step for 3D printing for the water sector is the diversity of materials.

At the tail end of 2022, United Utilities and tech innovators ChangeMaker3D achieved a first in the UK water industry by demonstrating the use of 3D concrete printed components.

Over the course of a year, ChangeMaker3D designed, 3D-printed and installed a wastewater chamber at one of the utility company’s test facilities in Cheshire in what has become known as 'Printfrastructure'.

The project delivered a 25 per cent reduction in carbon, 20 per cent cost saving and 55 per cent reduction in labour versus traditional methods.

United Utilities’ chief engineer (innovation), Lisa Mansell speaking on the project, said: “Digital technologies such as 3D construction printing can drive efficient construction and help us meet our Net Zero goals for carbon.”

Applications for 4D printing

Just when 3D printing seemed to be the new kid on the block, scientists at the Massachusetts Institute of Technology (MIT) have developed an additional concept.

Essentially, 4D printing refers to 3D printing objects that can re-shape if they come into contact with a specific energy source, such as light, heat or even water.

It works by strategically positioning rigid and expandable materials next to one other within one 3D-printed component.

Already the technology is to be tested to see if it can create self-repairing water pipes that change sizes in relation to water flow, or even in hot and cold temperature water valves.

We promise never to send you spam and you can unsubscribe at any time!