Manchester’s next membrane marvel? Spin-out secures £500k funding

A 2D membrane manufacturer spun out of the University of Manchester has raised £500,000 to scale up its new membrane coating.

A breakthrough for water filtration?

A 2D membrane manufacturer spun out of the University of Manchester has raised £500,000 in seed capital to scale up its new membrane coating.

The team from Molymem have used a two-dimensional version of modified molybdenum disulphide (MoS2).

This is partly made up of a natural crystal with physical properties that work well with graphene, the world’s first 2D material.

The technology was developed by research from Professor Rob Dryfe and Dr Mark Bissett at The University of Manchester in partnership with the University's Graphene Engineering Innovation Centre (GEIC).

Cambridge Angels, Manchester Angels and NorthInvest, made up the £500,400 private investment.

“The application of 2D advanced materials into water filtration technologies will, we are confident, help provide solutions to this critical global challenge,” said Ray Gibbs, chairman and director at Molymem.

What is a 2D membrane?

The latest membrane development raises the question of what is a 2D material?

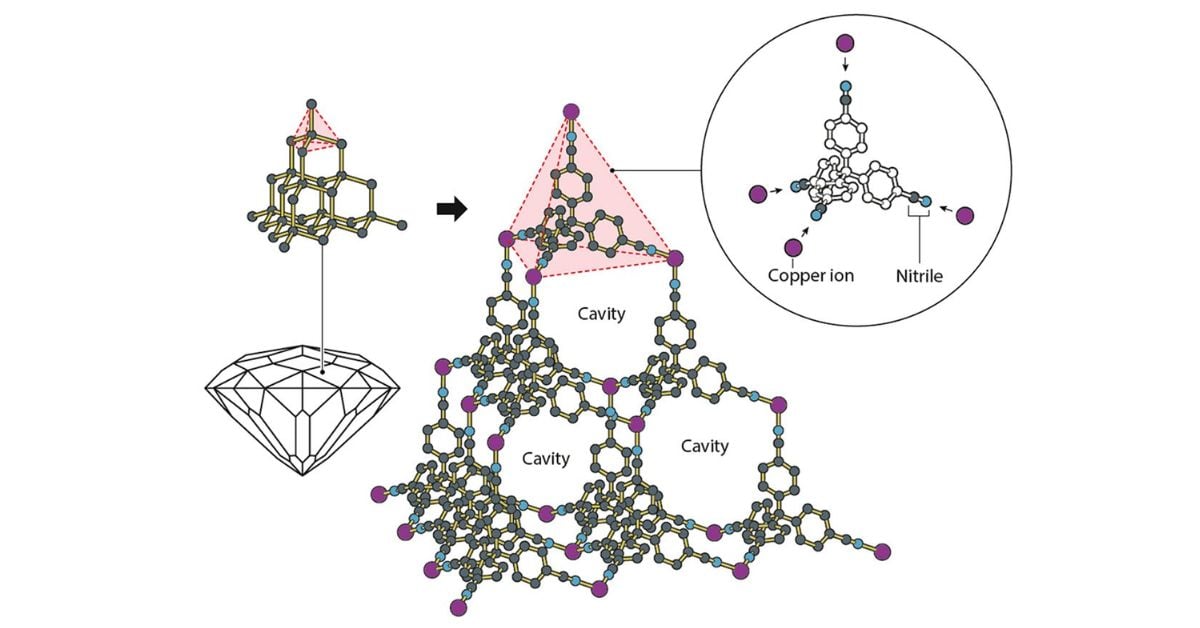

2D material is a single layer of crystalline solids consisting of a single layer of atoms, such as graphene. When 2D materials are stacked on a nanoscale, they form a 2D membrane, which has the potential for gas and liquid separation.

Molymem has used a two-dimensional version of MoS2 for its membrane coating, which it said can be retrofitted to existing membranes.

The Molymem platform can be tailored to reject target particulates such as nitrates, phosphates, PFAS/PFOS, dissolved organics, heavy metals and other pollutants.

The start-up believes that the MoS2 development can add value to existing membrane systems by reducing particulate clogging of the current filter, extending the product lifespan and reducing the use of chemicals and increasing flux.

"The Molymem platform can be tailored to reject target particulates such as nitrates, phosphates, PFAS/PFOS, dissolved organics, heavy metals and other pollutants,” said Richard Lydon, a filtration expert and senior advisor to Molymem.

"Water and wastewater treatment plants across the world need to be upgraded to keep pace with legislation and the ever-growing demand for drinking water.”

2D to 3D

While 2D membranes continue to gain traction, another membrane development is worth watching.

Evove, formerly graphene company G2O Water Technologies, has turned to 3D industrial printing at scale.

The company claims that its ‘Separonics’ product line can transform membranes to recycle water and recover valuable resources at a reduced price point.

At the end of 2021, the company signed a Joint Development Agreement with Meta Additive to produce an advanced additive manufacturing solution to 3D print its ceramic membranes, with plans to deploy in 2023.