Mobile unit destroys PFAS without secondary waste

Groundwater contaminated with per- and polyfluoroalkyl substances (PFAS) will be treated by a fully automated and remotely monitored mobile pilot plant solution operated by Swiss-based water tech company Oxyle.

Testing configurations for total PFAS elimination

The pilot is set to run for several months in Belgium. It will treat soil-wash water while testing several different process configurations. The test will identify the most efficient tech configuration and the best way to integrate Oxyle's PFAS destruction solution into the local water cycles.

For Oxyle, the pilot represents an expansion in scale and scope for its mobile pfas destruction unit and a real-world test of project efficiency and quality.

Dr Fajer Mushtaq, CEO and co-founder told Aquatech Online: "PFAS contamination is a critical issue affecting soil health across the world. The insights we gain from this pilot extend far beyond any one site, they are paving the way for the first truly effective and scalable solution to combat PFAS-contaminated soil globally."

PFAS destruction technology

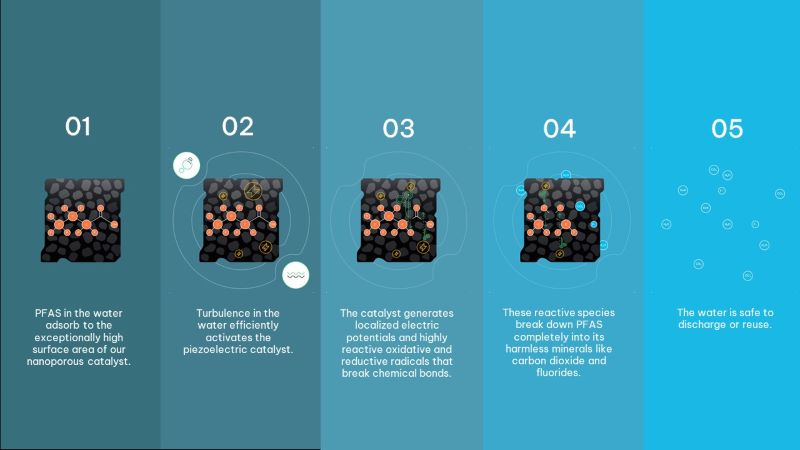

Oxyle's solution uses catalyst activated by turbulence in water to break down and mineralize broad-spectra PFAS (from ultra short to long-chain) into harmless by-products like fluoride ions, sulfate ions, and carbon dioxide.

The mechanical activation of the catalyst can be achieved using established water treatment technologies such as turbulent flow or aeration. And because the PFAS are destroyed on a molecular level there is no secondary waste, which means there is no need for any further waste management.

According to Oxyle, the process uses less than 1 kWh/m³, helping to reduce operating costs when compared to similar solutions.

Monitoring the solution

The project will use remote monitoring via proprietary real-time technology to validate the success of the treatment. This real-time remote monitoring will allow the process to be refined and optimised to adjust to fluctuating inlet concentrations.

The validation process will also help to further tailor the mobile unit ahead of a full-scale implementation.

We promise never to send you spam and you can unsubscribe at any time!

.jpg?h=400&iar=0&w=1140)