Unlocking the potential of recycling reverse osmosis membranes

As these membranes reach the end of their lifecycle - marked by performance decline due to fouling and degradation - the conventional approach has been to discard them, generating 14,000 tons of plastic waste annually in the process. Now, an environmentally conscious and economically viable alternative to this practice has arisen.

Transforming Waste into Opportunity

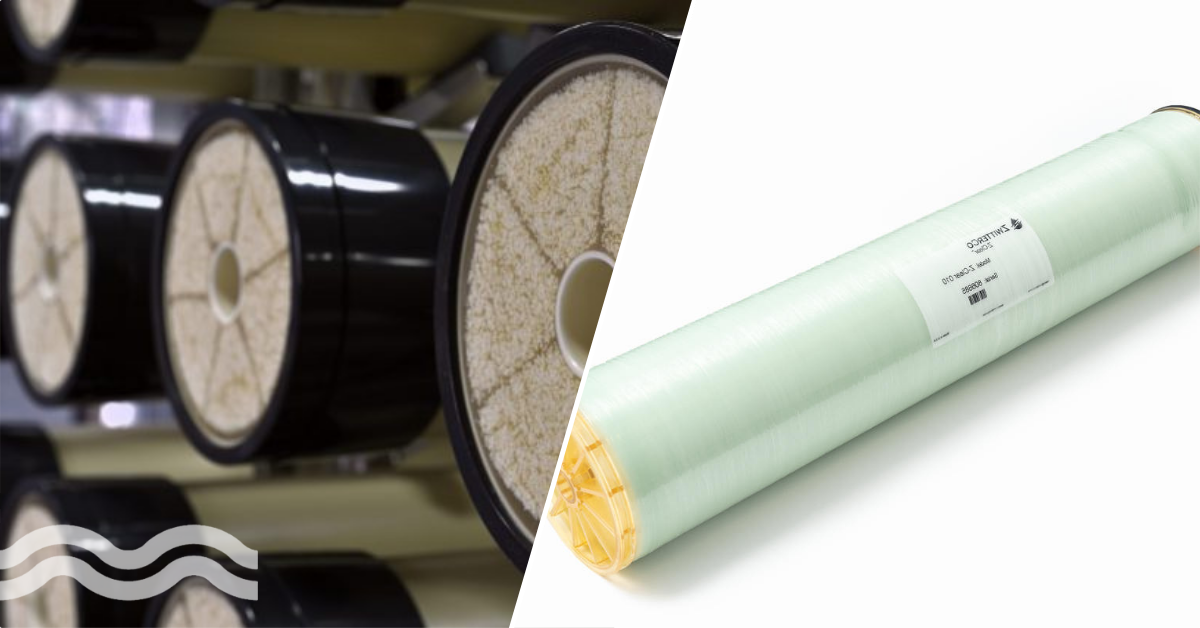

RO membranes are complex, multilayered systems designed to purify water by removing salts and contaminants. They are generally composed of a polyester mechanical support layer, a microporous polysulfone layer followed by a dense, surface polyamide layer, responsible for rejection of salts and other dissolved impurities. This surface layer is, however, prone to degradation over time, and will reach their end-of-life utility after approximately 24 months, at which point they are disposed of and replaced.

Rather than disposing of these membranes in landfills, research spearheaded by IMDEA Water in Spain has pioneered a method to repurpose them. The process uses a sodium hypochlorite oxidation step to strip the compromised polyamide layer, thereby transforming spent RO membranes into efficient nano- and ultrafiltration (NF/UF) membranes.

The beauty of this method lies in its adaptability. By carefully controlling the exposure to sodium hypochlorite, and thereby the degree of oxidation, the treatment can yield either NF or UF membranes, depending on the performance characteristics needed. This transformation not only extends the lifespan of the membranes but also addresses a critical environmental challenge.

Real-world Applications and Performance

The performance of recycled RO membranes has been tested and has shown promise across a range of applications, including brackish water treatment, tertiary wastewater treatment, and greenhouse drainage water treatment, and as a pretreatment step in RO desalination processes. In testing, the recycled RO membranes have performed comparably to virgin UF/NF modules, as noted in a briefing at the IDA Water Recycling and Reuse Conference in 2021.

A significant example of their successful application has been in the treatment of landfill leachate (LFL). This highly contaminated wastewater, typically difficult to treat, has shown promising results when processed through recycled RO membranes. In a 27-month study involving IMDEA and the University of Girona, second-hand RO membranes from seawater desalination plants were repurposed for LFL treatment. These membranes consistently produced permeate water that met regulatory standards while using significantly less energy than traditional methods.

The Economic and Environmental Impact

The market potential for RO membrane recycling is notable. With the cost of producing recycled NF and UF membranes significantly lower than that of virgin membranes, and the lifespan of recycled membranes being approximately 75% that of virgin RO membranes, industries stand to benefit from substantial cost savings. A typical recycled membrane module can be produced for under €100, far below the €400 to €800 price range for new modules. Moreover, the recycling process aligns with circular economy principles, reducing both the environmental footprint and reliance on raw materials like petroleum-based plastics.

From an environmental perspective, the benefits are equally compelling. Life cycle assessments (LCAs) conducted by IMDEA Water highlight several critical areas of impact reduction:

- Global warming potential: Recycling membranes reduces greenhouse gas emissions by minimizing the need for energy-intensive production of new membranes.

- Marine eutrophication: By preventing the release of nutrient-rich waste into aquatic ecosystems, membrane recycling mitigates the risk of marine eutrophication.

- Fossil resource depletion: Repurposing spent membranes decreases the demand for raw materials, slowing the depletion of fossil resources.

These advantages highlight the broader implications of RO membrane recycling, not only for water treatment but also for addressing global environmental challenges. As water scarcity becomes more pronounced, the need for efficient, sustainable solutions like membrane recycling will only increase.

Overcoming Challenges

While the potential for RO membrane recycling is clear, several challenges remain. One of the main limitations is the variability in membrane performance after recycling. Though careful sorting and characterization can mitigate some of this variability, it introduces additional complexity into the process. The physical state of the membranes is another concern as any structural damage incurred during their first life must be carefully assessed to avoid operational failures in their second life.

Geographic factors also play a role in determining the feasibility of recycling. The proximity of recycling facilities to sources of spent membranes can significantly impact both the economic and environmental viability of the process. Transportation costs and the carbon footprint associated with moving used membranes to recycling plants must be considered in strategic planning.

Finally, regulatory frameworks have yet to catch up with the advancements in membrane recycling. As of now, there are no standardized guidelines in the European Union or the United States for the inspection, recycling, and reuse of spent RO membranes. Developing these regulations will be essential for ensuring that recycled membranes meet safety standards and can be used confidently in water treatment applications, including drinking water filtration.

The Road Ahead

Despite the challenges, the future of RO membrane recycling is bright. With predictions that the desalination sector will generate two million end-of-life RO modules by 2025, the market for recycled membranes is poised for rapid growth. By establishing more recycling facilities and improving membrane performance characterization technologies, the industry can create a sustainable, cost-effective supply chain that benefits both the environment and the bottom line.

Partnerships between desalination utilities, industrial water treatment facilities, and regulatory bodies will be crucial in driving this change. By fostering collaboration, establishing market outlets for recycled membranes, and creating innovative financial models, the water treatment industry can make significant strides toward a circular economy.

Conclusion

RO membrane recycling offers a compelling solution to the growing problem of plastic waste in the water treatment industry. With proven performance in challenging applications like landfill leachate treatment and the potential for significant cost savings, recycled membranes present a viable alternative to virgin products. As the industry evolves, overcoming the challenges of membrane performance variability and regulatory gaps will be key to unlocking the full potential of this innovative approach.

Incorporating RO membrane recycling into water treatment practices is not just a technical achievement - it represents a shift toward more sustainable, responsible resource management. By transforming waste into a valuable resource, the water industry is taking a crucial step toward a greener future.

We promise never to send you spam and you can unsubscribe at any time!