Decarbonised ammonia production treats nitrate-contaminated water

The development of a reactor that decarbonises the production of ammonia has the potential to remove the need for denitrification at wastewater plants.

Converting nitrates into ammonia

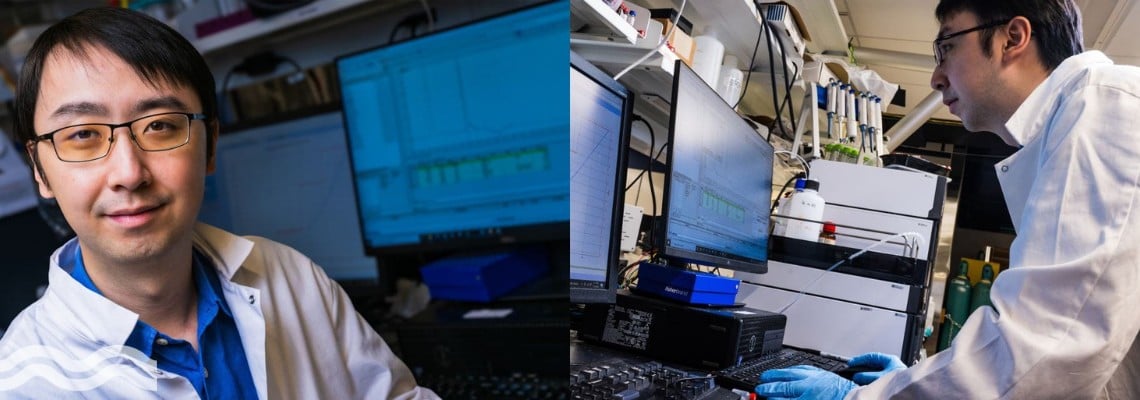

The research was carried out by a team of engineers led by Haotian Wang at Rice University in Houston, Texas; it was published in Nature Catalysis. The reactor system converts nitrates, which are common pollutants found in industrial wastewater and agricultural runoff, into ammonia, a vital chemical used in fertilizers, and therefore plays a critical role in sustaining food production for the world’s growing population.

Ammonia is also used in a wide range of industrial and commercial products, from household cleaners to plastics, explosives and fuel. However, as one of the world’s most widely produced chemicals, its production accounts for about 2 per cent of global energy consumption and 1.4 per cent of carbon dioxide emissions.

An alternative production process

The main way to make ammonia is the Haber-Bosh process, which entails a reaction between hydrogen and nitrogen that occurs under high temperature and pressure conditions and is dependent on large-scale centralized infrastructure.

However, an alternative is to use electrochemical synthesis, which involves the use of electricity to drive chemical reactions.

Feng-Yang Chen, a Rice graduate student, and lead author on the study, told media: “Electrochemistry can occur at room temperature, is more amenable to scalable formats for different infrastructure systems, and has the capacity to be powered by decentralized renewable energy.”

In simple terms, you put wastewater in, and you get pure ammonia and purified water out

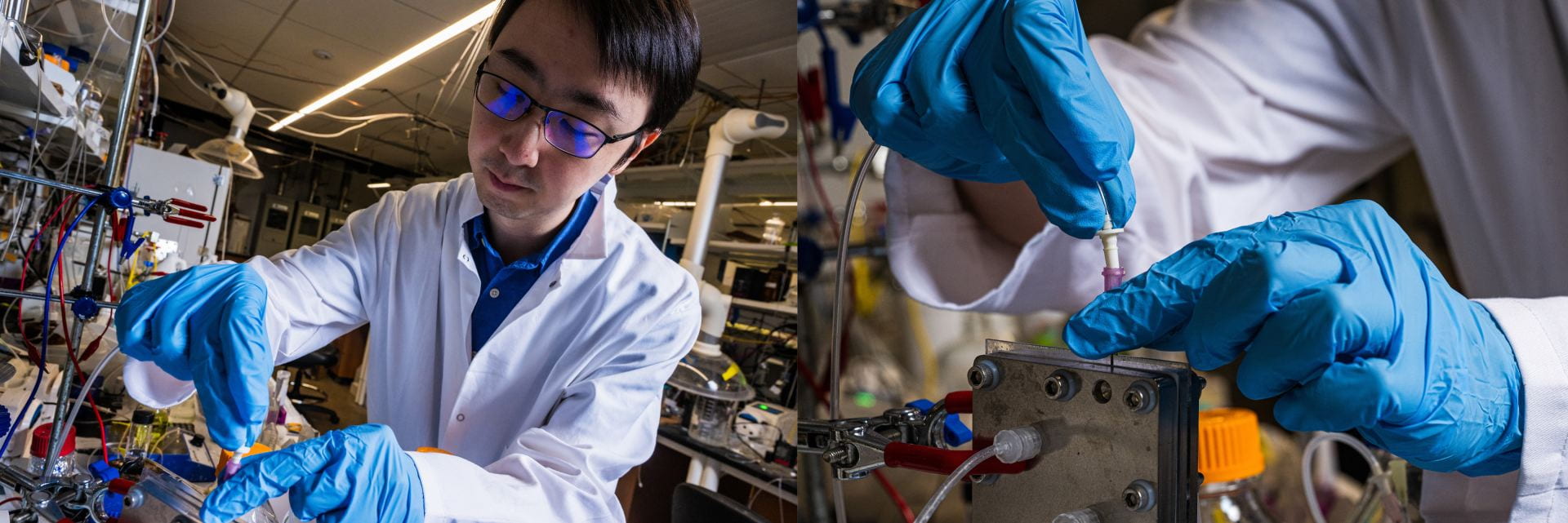

He added: “However, the current challenge for this technology is that large quantities of additive chemicals are required during the electrochemical conversion process. The reactor we developed uses recyclable ions and a three-chamber system to improve the reaction’s efficiency.”

Pure ammonia and clean water

The system uses of a porous solid electrolyte, which eliminates the need for high concentrations of supporting electrolytes - an issue that has hampered previous attempts to convert nitrates to ammonia sustainably. A future application that powered the conversion process with renewable energy would render ammonia production through this process effectively carbon-neutral.

The experiment flowed nitrate-contaminated water through this reactor and measured the amount of ammonia produced and the purity of the treated water.

“We discovered that our novel reactor system could turn nitrate-contaminated water into pure ammonia and clean water very efficiently, without the need for extra chemicals,” Chen explained. “In simple terms, you put wastewater in, and you get pure ammonia and purified water out.”

Removing the need for nitrification

The system makes possible an electrochemical nitrate-to-ammonia conversion pathway that would eliminate the need for denitrification at wastewater treatment plants.

Pedro Alvarez, the George R. Brown professor of Civil and Environmental Engineering, director of the Nanosystems Engineering Research Center for Nanotechnology-Enabled Water Treatment (NEWT) and the Water Technologies Entrepreneurship and Research (WaTER) Institute at Rice University told media: “Nitrate is one of the priority pollutants that most frequently violates drinking water standards, and it is a significant concern in growing cities as farmland with nitrate-contaminated groundwater supplies is converted to urban development.”

It offers a solution that eliminates nitrate toxicity and associated liability without the need to add treatment chemicals

Alvarez added: “Conventional nitrate removal in drinking water treatment involves ion exchange or membrane filtration by reverse osmosis, which generates brines and transfers the nitrate problem from one phase to another.” Professor Wang’s innovation is very timely and important, as it offers a solution that eliminates nitrate toxicity and associated liability without the need to add treatment chemicals.

Beyond ammonia, future reactor research

According to the research team, the implications of this work extend beyond ammonia production. They believe that the design of the reactor and the study’s accompanying techno-economic assessment can help inform further research into other eco-friendly chemical processes, potentially transforming how industries address environmental challenges.

Wang said: “Our findings suggest a new, greener method of addressing both water pollution and ammonia production, which could influence how industries and communities handle these challenges. If we want to decarbonise the grid and reach net-zero goals by 2050, there is an urgent need to develop alternative ways to produce ammonia sustainably.”