Cerafiltec to provide flat membranes to four bioreactor projects

German membrane specialist company Cerafiltec will provide ceramic flat membranes to membrane bioreactor (MBR) projects on four different continents.

Flat membranes for wastewater treatment

Cerafiltec's filters will be used in for wastewater treatment in four membrane bioreactor (MBR) projects located in Italy, Mexico, the UAE and Africa. At each site, Cerafiltec's ceramic flat membranes will replace traditional polymeric membranes, both hollow fibre and flat sheet.

The membranes will handle a total capacity of 13.7 million litres per day across all four sites, ranging from a 250 m³/d industrial MBR to a larger 10,000 m³/d municipal MBR.

How the flat membranes work

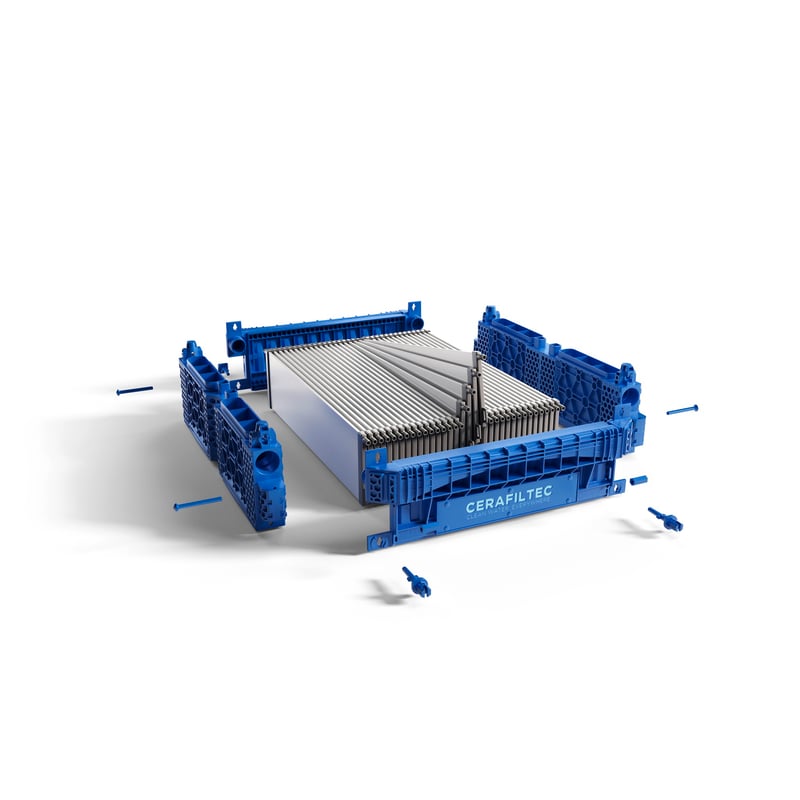

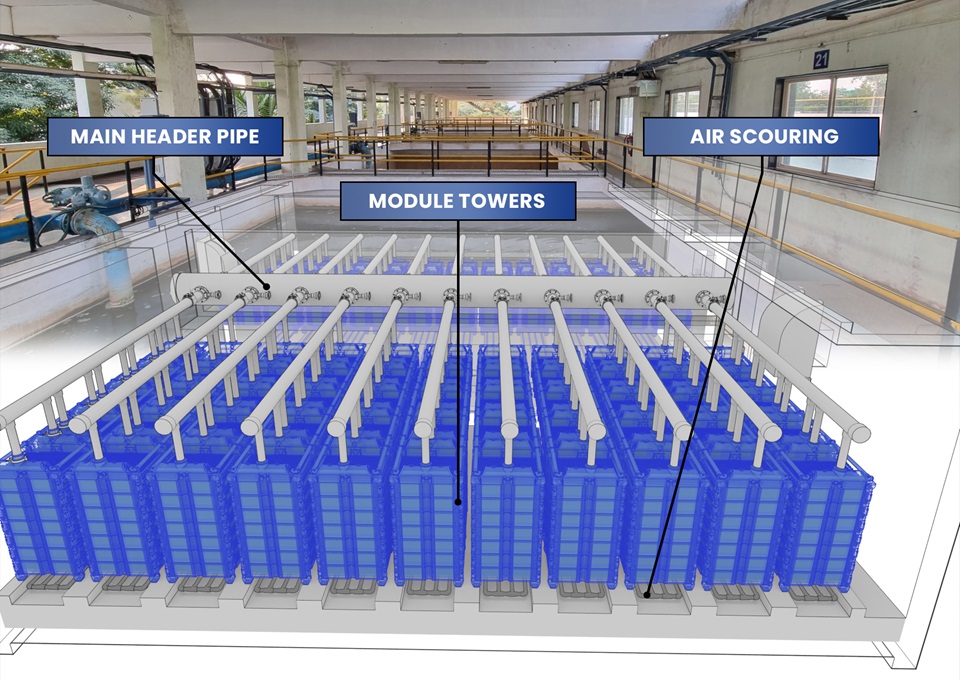

Each flat membrane plate has two filtered water outlets on each side, these membranes can be arranged into a module that can contain up to 34 interchangeable membranes with internal filtered water piping. The number of membranes can be reduced to increase spacing in high sludge applications to help avoid clogging.

Up to 16 modules can be stacked into a tower, which can then be connected via a common pipe to other towers creating a modular and scalable solution.

As there is no metal used in the construction, the flat membranes provide a number of benefits, including a high flux operation requiring less filter areas, leading to high CAPEX savings. The system can be used for challenging applications without any risk of corrosion and can be used with hot water, up to boiling.

A clear indicator of the global market's growing appreciation for the advantages of ceramic flat membranes

Julius Gloeckner, chief growth officer at CERAFILTEC, told Aquatech Online: “At CERAFILTEC, we are driven to transform the water filtration industry by enabling ‘clean water, everywhere’. The superior properties of ceramic materials make them particularly suitable for all water and wastewater treatment applications, where durability and reliability are critical.”

He added: “Commercially, ceramic membranes are already driving substantial OPEX advantages over polymeric membranes, with continuous development and improvements in ceramic membrane technology increasing untapped savings. Our long-lasting, reusable solutions reduce maintenance and replacement needs, helping clients achieve their filtered water targets effortlessly. This enhances efficiency and profitability while also fostering a circular economy.”

The successful acquisition of these projects is a clear indicator of the global market's growing appreciation for the advantages of ceramic flat membranes.

We promise never to send you spam and you can unsubscribe at any time!

.jpg?h=400&iar=0&w=1140)