ESSENTIAL GUIDE: Biogas – an untapped energy source

Table of contents

- A two-stage process to remove pharmaceuticals

- How is biogas produced?

- What is biogas used for?

- How does biogas production work?

- Biogas vs natural gas

- How is biogas formed?

- What is a biogas plant?

- Where is biogas used?

How can biogas be further harnessed to be part the renewable energy mix to help with decarbonisation? Aquatech Online explores the topic further in this preview article of the ‘Essential Guide’.

A two-stage process to remove pharmaceuticals

Biogas, an untapped energy source that has the potential to help the water sector decarbonise and tackle the climate crisis. Continuing to be explored and scaled, biogas is a viable, sustainable and environmentally-friendly alternative way of generating energy to natural gas.

With more and more companies committing to decarbonisation in the next few years, biogas could play a key role in achieving this target. But how revolutionary could it be? How is it produced? How can existing wastewater treatment plants be upgraded into “resource” generating facilities, including biogas?

How is biogas produced?

Biogas is produced through the process of anaerobic digestion, which is a type of decomposition that occurs in the absence of oxygen, according to the National Grid.

Biogas, derived from sources like agricultural waste, food waste, animal manure, and sewage sludge, results from organic matter combining with water in a digester. Microorganisms break down this mixture, producing methane and carbon dioxide as by-products.

Biogas production can also yield small amounts of hydrogen sulphide, siloxanes, and moisture, with quantities varying based on the waste type. Microbes are crucial in the process, feeding on biomass through several stages:

-

1. Biowaste is crushed and converted into slurry for anaerobic digestion.

2. Biowaste is heated to around 37 °C, as microbes need warm conditions

3. Anaerobic digestion occurs in large tanks over three weeks.

4. In the final stage, gas is purified by removing impurities and carbon dioxide.

According to the Anaerobic Digestion and Bioresource Association (ADBA), biomethane can directly displace fossil gas, providing a low-carbon fuel for domestic and commercial heat.

Within biogas, methane content typically ranges from 45 per cent to 75 per cent by volume, with the remainder being carbon dioxide, added the International Energy Agency.

As a result, biogas energy content can vary. For example, the lower heating value (LHV) is between 16 megajoules per cubic metre (MJ/m3) and 28 MJ/m3.

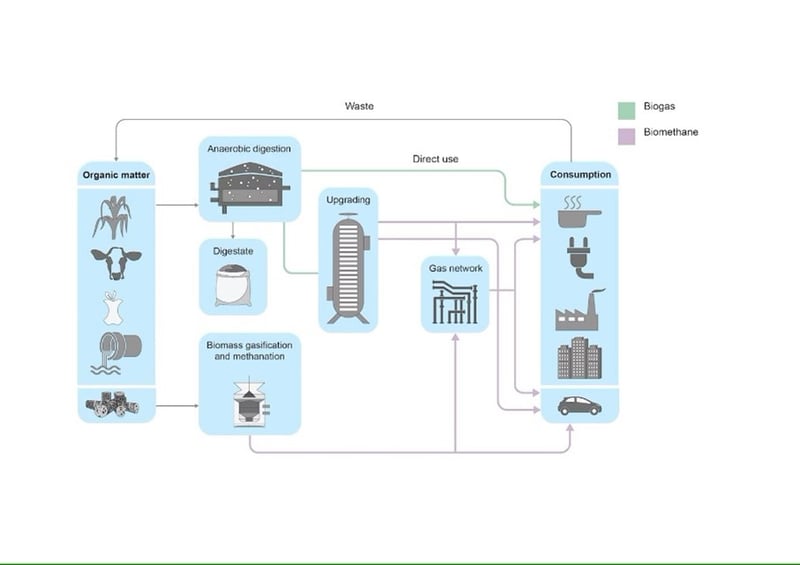

Biomethane is a near-pure source of methane produced either by “upgrading” biogas - a process that removes any carbon dioxide and other contaminants present in the biogas through the gasification of solid biomass followed by methanation.

Biogas production reduces the amount of organic matter that would otherwise end up in landfills. It reduces greenhouse gas emissions by capturing methane, a potent greenhouse gas, and using it as a source of energy.

What is biogas used for?

Biogas serves multiple purposes, from heating and fueling vehicles to generating electricity for homes and businesses through combustion in a generator.

Buses, trucks, and cars can run on biogas. In 2017, Queensland Urban Utilities unveiled the world's first “poo-powered car,” fuelled by biogas from sewage at the Oxley Creek Sewage Treatment Plant in Brisbane's west.

In 2011, one of the UK's first biogas plants launched under the government's Renewable Heat Incentive scheme. By 2016, the UK built 33 new plants, according to the ADBA.

UK's food waste presents a significant resource for biogas generation, with an estimated 10 million tonnes annually from households, food service, manufacturing, and wholesale sectors, per WRAP.

Processing this organic waste through anaerobic digestion (AD) could generate 11 terawatt hours (TWh) of biogas. This would heat 830,000 homes and reduce emissions by 8.8 million tonnes of CO2 equivalent, accounting for 2% of the UK's annual emissions.

In comparison, across the 50 US states, over 2,200 sites produce biogas. These include 1,269 water resource recovery facilities using anaerobic digestion (AD), 652 landfill gas projects, 250 farm-based digesters, and 66 stand-alone systems digesting food waste, as reported by the American Biogas Council.

Biogas usage extends to industrial processes like chemical and plastic production, contributing to waste reduction and lower greenhouse gas emissions, thus supporting a shift toward sustainability.

Image credit: IEA

How does biogas production work?

In 2019 there was a total of 132,000 small, medium or large-scale digesters were operating globally, according to the World Biogas Association.

Biogas plants typically have three major components: a reception area, a digester (or fermentation tank) and a gas holder.

There are several types of digesters that can be used to produce biogas, including continuous flow digesters, batch digesters, and plug flow digesters. The type of digester used will depend on the specific needs of the biogas production facility and the type of organic matter being used.

To maximise the efficiency of the anaerobic digestion process, it is important to maintain the proper temperature and pH levels inside the digester. Microorganisms that produce biogas are sensitive to changes in these conditions, and fluctuations can impact the rate at which biogas is produced.

Once the anaerobic digestion process is complete, the remaining material, called digestate, can be used as a fertilizer for crops. This makes biogas production not only a source of renewable energy but also a way to reduce waste and improve soil health.

According to a report from the Global Biogas Association (GBA), adding anaerobic digestion treatment to centralised wastewater treatment facilities to generate biogas could help reduce global greenhouse gas (GHG) emissions by over 10 per cent.

Furthermore, the generated electricity could meet the needs of almost 40 million people globally.

Biogas vs natural gas

Biogas and natural gas are both energy sources for heating, cooking, and electricity generation, yet they differ in several ways.

One of the main differences between biogas and natural gas is the way in which they are produced. As a fossil fuel, natural gas is formed over millions of years from the decomposition of organic matter.

When compared to natural gas obtained by drilling into the earth, biogas is clearly a more sustainable option, said the World Wildlife Fund (WWF).

On the other hand, Biogas is generated via anaerobic digestion, a form of decomposition that happens without oxygen.

Another difference between the two is the composition. Natural gas consists mainly of methane, whereas biogas comprises methane, carbon dioxide, and hydrogen sulphide, among other gases.

The exact composition of biogas can vary depending on the specific feedstocks used in the anaerobic digestion process.

Biogas is often viewed as a more sustainable energy source than natural gas, with added benefits such as removing food waste and animal manure from the environment, thus preventing nitrogen pollution and run-off into water resources.

Furthermore, biogas also helps to mitigate methane emissions from landfill sites or manure lagoons. By using methane, which is up to 34 times less potent as a greenhouse gas, as a fuel it can help to reduce its climate impact, the WWF said.

However, while biogas is known as renewable natural gas, the definition of “renewable” should be used carefully when discussing waste streams. According to the WWF, it is “renewable” in the sense that animals and humans will continue to produce this waste stream. Simply put: generating more waste to create more biogas should not be encouraged.

However, biogas is a more sustainable solution than traditional natural gas and it can be used to help with the fuel transition to help decarbonize existing energy supplies.

How is biogas formed?

Biogas is formed through the process of anaerobic digestion, which is a type of decomposition that occurs in the absence of oxygen.

This process is carried out by microorganisms, which break down organic matter and convert it into biogas.

A variety of organic matter can be used to produce biogas, according to the IEA:

- Crop remains: maize, wheat, rice and other course grain residues, as well as soybean, sugar beet and other oilseeds.

- Animal waste: From livestock such as cattle, pigs, poultry and sheep

- Organic compounds: Food and green waste such as grass and leaves, wood, paper and cardboard otherwise not used

Wastewater sludge: Semi-solid organic matter recovered in the form of sewage gas from wastewater treatment plants.

To maximise the efficiency of the anaerobic digestion process, it is important to maintain the proper temperature and pH levels inside the digester.

The microorganisms that produce biogas are sensitive to changes in these conditions, and fluctuations can impact the rate at which biogas is produced.

What is a biogas plant?

A biogas plant is a facility that converts organic matter, such as animal waste or agricultural waste, into biogas. The facility provides oxygen-free conditions where anaerobic digestion can occur.

In essence, it’s an artificial system where you can turn waste into sustainable energy and fertilisers, with positive effects on the environment.

The production of biogas in a plant can be broken down into five steps:

- Pre-treatment and filling of the digester

- Fermentation process

- Production of the biogas

- Pulling out the residues

- Removing any impurities.

Energy produced from biogas can be stored or injected into the electricity grid to reduce dependence on fossil-fuel energy, which can in turn help reduce our carbon footprint.

Another advantage of biogas plants is that they eliminate the need for synthetic fertilisers, as they get replaced by digestate.

In terms of regions, Europe is the largest producer of biogas, with Germany being by far the largest market, and home to two-thirds of Europe’s biogas plant capacity, said the IEA.

Data from the European Biogas Association (EBA) revealed that Europe beat its record in 2021 with an “exponential deployment of biomethane plants”.

Whereas in China, policies have supported the installation of household-scale digesters in rural areas to increase access to energy and clean cooking fuels; these digesters account for around 70 per cent of its installed biogas capacity.

India has laid out plans to develop around 5,000 new compressed biogas plants by 2024, as part of a Global Methane Initiative commitment.

Where is biogas used?

Biogas has five main uses, according to the ADBA.

These include heat generation, transport, electricity, carbon reduction and the development of bioresources.

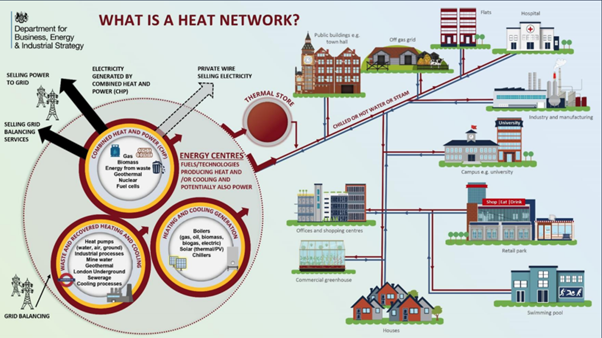

Heat represents one of the hardest sectors to decarbonise in the UK. The entire energy network has been built to suit fossil fuels, from gas transmission to domestic boilers. ADBA suggests that only biomethane can directly replace fossil natural gas.

Currently, biogas is most commonly used as a fuel in combined heat and power (CHP) units.

These units generate renewable electricity and primary heat, which can be exported to the national grid and piped within local heat networks, respectively, added the ADBA.

Biomethane serves as a transport fuel, offering substantial environmental and cost benefits over diesel for HGVs, buses, and other vehicles. It also contributes to enhancing air quality in urban areas.

As a commercial example, John Lewis Partnership invested in 43 dual-fuel trucks, 12 dedicated gas trucks, and a filling station near Leyland to adopt biomethane. Their goal is to have 700 biomethane trucks by 2024.

ADBA discovered that utilizing all suitable UK feedstock for anaerobic digestion could produce enough biomethane to heat 6.4 million homes or fuel 97% of the UK's HGVs.

Source: Department of Business, Energy & Industrial Strategy, UK Government.

We promise never to send you spam and you can unsubscribe at any time!