ReWater: Digitally mapping the resource recovery plant of the future

The ReWater project from Aarhus Vand and partners Black and Veatch are using novel digital technologies to help develop a pathway to clean water and resource recovery.

Recovery of water resources

With ambitions to develop the world’s most resource efficient wastewater treatment plant, Denmark’s Aarhus Vand is relying on digital technology to help it plot a route to its long-term goal.

The ReWater project will see a wastewater treatment plant developed near Marselisborg in Denmark. Once completed in 2028, this plant will not only include the world’s most advanced water treatment technologies, but also a technology development pathway that will keep the utility at the forefront of water treatment tech.

To ensure both an economically and environmentally optimised wastewater infrastructure for the future, Aarhus is putting digital technology at the heart of its operation.

In a recent webinar, Aarhus Vand’s chief digital information officer Jesper Kjelds and Black & Veatch’s head of digital products and services for Europe Chris Steele, explored the role of data-driven asset management and the value it is bringing to the Aarhus Vand technology roadmap.

“To ensure both an economically and environmentally optimised wastewater infrastructure for the future, Aarhus is putting digital technology at the heart of its operation.”

The roadmap stems from a 2005 decision taken by Aarhus City Council to optimise the wastewater structure in the municipality. The plan envisaged consolidating the wastewater treatment operation into two large-scale and much more efficient plants that are estimated to reduce operating costs by 40 per cent.

Of the two wastewater treatment plants, Egaa has already undergone an extensive energy renovation and today produces more electricity than it uses. The existing Marselisborg plant, located at Tangkrogen near the Marselisborg Forest and harbour, proved to be too small to meet future demand and will be replaced with the ReWater installation nearby.

However, while setting out its ambitious goals, Aarhus Vand acknowledges that it doesn’t know precisely what technologies will feature in the facility.

Instead, it has established 15 innovation challenges that it aims to address as part of a development programme through to 2028 and beyond.

Building flexible innovation through challenge

Among these challenges, Aarhus Vand is exploring how to support constant changes and flexibility in relation to new demands and system exports. For instance, the company notes that microplastics, pharmaceutical compounds, pathogens, hormones and pesticides might be substances that need to treated in the future.

Aiming to address these challenges early in the process, Aarhus has invited companies, manufacturers, research institutions and individuals to engage in the project with products, services, knowledge, and know-how.

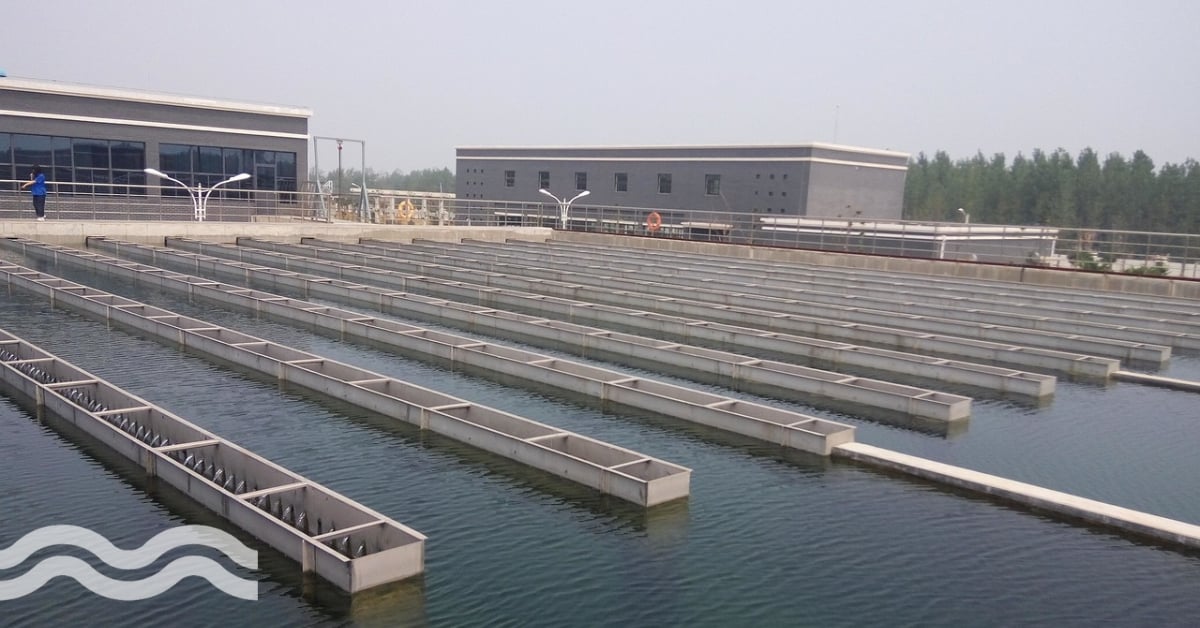

Ultimately the goal is to establish not only a wastewater treatment plant but a resource plant which will also produce energy and nutrients from the wastewater to an unprecedented extent.

In utilising these resources, the costs of wastewater treatment will be mitigated through the sale of energy, extraction of resources such as heavy metals, phosphorus and plastic, or cultivation of crops that both cleans and can be used for fuel or industrial production.

“Aarhus ReWater, to our knowledge, is the most ambitious wastewater treatment plant but we’d rather call it resource recovery plant,” says Kjelds.

Creating a treatment test-bed

Furthermore, Aarhus believes that the task is not to build a finished plant, but to build a demonstration and test platform.

As envisaged, ReWater will be able to meet existing demands, but 10-20 per cent of the modular structure will be adaptable to serve as a test-bed where new or optimised treatment processes can be explored at scale in a real operating environment.

“What’s exciting about ReWater is that we are thinking of three different treatment lines. A traditional wastewater treatment considering effluent discharged into the bay with the regulations and threshold levels for effluent discharge,” says Kjelds, adding that a second line is focused on resource recovery.

“This is where we have different projects that will recover resources from the waste stream. Today we’re looking at energy, we’re looking at Struvite [magnesium ammonium phosphate] or phosphorus and then potentially it could be proteins, it could be other resources in the influent waste stream.”

Kjelds concludes: “A final line is experimental. That’s where we will innovate, develop and test different technologies that are being developed every day and will continue to develop. We test them there at scale and on the exact same wastewater. As the technologies develop, potentially it could be moved up to line two as, say, a recovery process.

“Aarhus has invited companies, manufacturers, research institutions and individuals to engage in the project with products, services, knowledge, and know-how.”

Aarhus has also turned to digital technologies as part of its technology roadmap. Aarhus Vand is actively using new (Water 4.0) IT technologies in combination with deep domain knowledge, experience and data to drive the transformation.

As Kjelds explains: “We’ve been working with data and digital for many years and have actually brought it into operations and are reaping the benefits of a lot of automation, specifically on wastewater collection and waste water treatment.”

Digital blueprint for water innovation

Alongside instrumentation and extensive sensor deployment, Aarhus uses model-based control of its entire systems together with optimised targets.

For example, Kjelds notes that the company actively forecasts rainfall events to manage collection of wastewater, which is combined to a large degree.

“Managing that in retention storage so that we can buffer capacities and reduce our over flows and also forecast the inflow to the treatment plants. We can optimise the operation of our treatment plant and at the treatment plants we are achieving maximum energy production and at a reduced energy consumption,” says Kjelds.

“We are building on that for our digitalization blueprint. Digital is then going to be both inside and outside of everything, so the data that we collect through IoT devices will be a crucial part of operating, maintaining and servicing the future ReWater plant. Digital is in the DNA of ReWater.”

“Digital is then going to be both inside and outside of everything, so the data that we collect through IoT devices will be a crucial part of operating, maintaining and servicing the future ReWater plant.”

Building a flexible, adaptable plant

Becoming data driven, ReWater aims to activate data to get insights, new information and develop new services based on the core of intelligent asset management decisions.

As Chris Steele says: “Digital goals are supported by a set of principles using industry best practice and the concept of a digital framework. It’s a playbook that you can pick up and use and follow and it’s clear and concise for the digital-related activities that Aarhus Vand undertakes.”

These same principles are being applied to the ReWater project.

Kjelds says: “The different technologies and processes will be mapped up against this technology radar. It gives a unified systemic approach to evaluation of new technology and also where should we put our focus and what needs to be developed even further and where do we need to look for partners and so forth.”

He concludes: “That is the blueprint that we are taking with ReWater in terms of a digital blueprint and mapping that across our data-driven asset management and across our water partnerships going into the future.”

The ambition for ReWater is not to build a plant that remains unchanged for a hundred years but a plant that constantly helps to expand the knowledge base and therefore can constantly be improved. Digital is at the heart of that process.