Aqualia bets on biosensors for better wastewater monitoring

A partnership between Spanish water giant Aqualia and Canadian start-up, Sentry is enabling real-time monitoring of organic content in water for treatment.

[Sponsored content]

The future of wastewater is bright

What will the wastewater treatment plant and network look like in the future?

While 'traditional' infrastructure takes human waste out of sight, out of mind to centralised plants, the future involves more sensors and data to drive a more intelligent network operation - including locations that allow easier resource recovery.

That's according to Frank Rogalla, director of innovation and technology and Jose Ramon Vazquez- Padin, area manager at the department of innovation of Aqualia.

Speaking to Aquatech Online, they enthusiastically believe that change is coming to wastewater treatment. And in a good way.

"In the future, there shouldn't be any waste," says Rogalla. "We say our biggest objective is not to talk about wastewater anymore. It's essentially water for reuse and much valuable material that we can extract."

By 2030 ambitions, Aqualia aims to ensure that 50 per cent of the energy it uses will come from renewable sources.

The organisation is well positioned to comment on where new solutions can best fit and offer value in the treatment landscape. Operating more than 500 wastewater and 200 drinking water treatment plants across 17 countries and 180,000 km of networks, Aqualia is the fourth largest water management company in Europe.

Part of the company's journey to 2030 includes to "digitalise our sewers", adds Vazquez-Padin, which he refers to as the "previous unknown world".

Getting to know the unknown

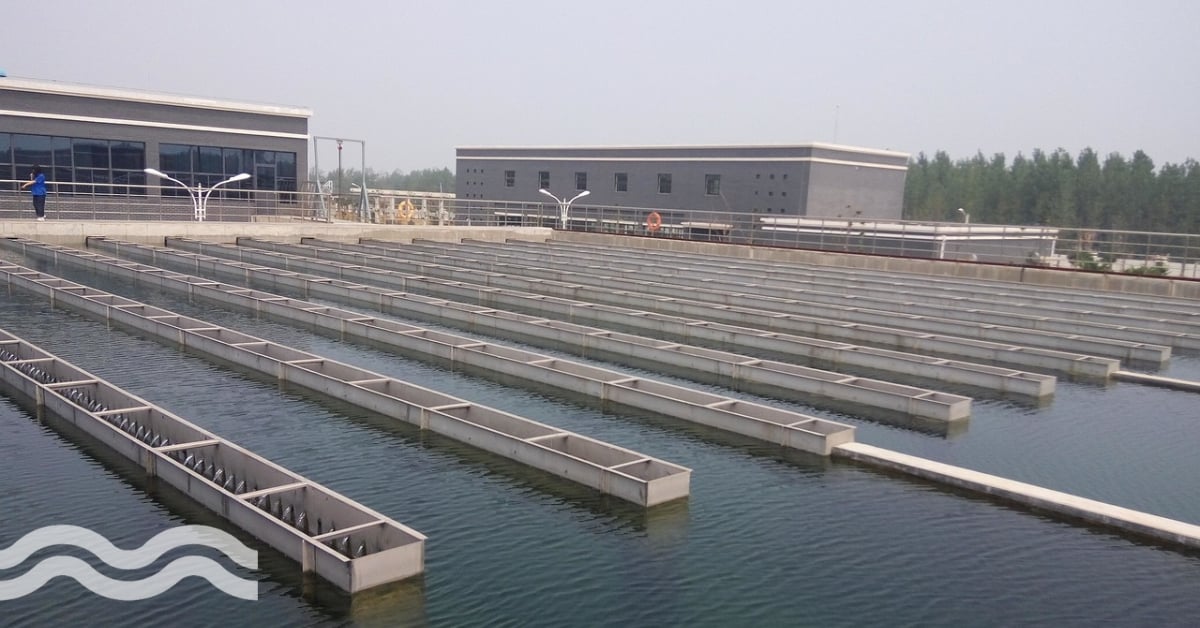

Aqualia sees a future where sensors provide more data throughout the wastewater process. This includes finding out who is discharging different types of organic content, to better controlling what is entering sewers and finding out the quantities of mixed rainwater and salty water.

Imagine a real-time view of wastewater, from collection to treatment and disposal. A 24/7 super network, essentially turning the unknown into the very well known.

Key to this wastewater treatment evolution is bio-electrode sensors and a global partnership with the Canadian organisation, Sentry. The two organisations came together at an Isle Utilities' Technology Approval Group (TAG) event, which aims to connect solutions to end-users.

"All of the industry is based on BOD – it's an irony."

What interested the Aqualia team was the ability to use microbial fuel cells (MFCs) as biosensors, given that current methods to measure BOD (biochemical oxygen demand) are "quite painful".

"All of the industry is based on BOD – it's an irony," remarks Rogalla. "It was invented in England almost 150 years ago because every river in the country took five days to go to the sea. That's the basis of all regulations worldwide.

"It's really painful because the result comes five days later, and you don't know how to handle it. Any new device that allows us to have more online information is very valuable. So, if there is a new development, we are eager to test it."

Sentry's starting point: ASBR

Following the TAG event, Aqualia started piloting Sentry's bio-electrode sensors in an industrial site and its own technology, based on an anaerobic sequencing batch reactor (ASBR). As an anaerobic process, the potential to have a probe to inform what the BOD content is in real-time "allows us to push the technology forward", adds Vazquez-Padin.

Two probes were installed, one before the reactor and one inside the reactor, to provide insight into how fast bacteria were processing organic matter and provide knowledge about the water entering the reactors.

"Real-time monitoring of the water entering our system gave us confidence and knowledge."

"At industrial sites, especially in industrial wastewater, many companies are doing their business and don't care too much about the treatment plant," adds Vazquez-Padin. "You don't have much information about what is coming to the end of the pipe."

He adds: "For us, real-time monitoring of the water entering our system gave us a lot of confidence and knowledge about the content and the organic content of the water we needed to treat."

To date, Sentry has installed 150 units, from the US and Canada, through to Europe, Saudi Arabia, Singapore and Australia. The company estimates that it has helped protect 26.2 million people across the watersheds it's monitoring.

Democratising access to sensors

A monitoring solution for aqueous environments, Sentry's sensors can provide insight into biological processes where water is used, stored and treated. The real-time performance monitoring can reveal whether there's high microbial activity, organic overloading, or low microbial activity, revealing a potential biological upset.

One of the benefits of the probe was the accessibility and simplicity of the system, according to Rogalla.

"Normally, when you have a new probe, you need a PhD-level staff member standing by to make sure it works – it can be complicated to run," he says.

"Especially with ASBR, even if it's a small unit, it's not easy and straightforward. Most people abandon the probe after a while because the operators cannot afford to maintain it, and it requires a dedicated effort."

An example of democratised access to biosensors and data?

"With the Sentry probe, it was quite easy. You have no maintenance, so you only have to plug the probe inside the tanks, and you don't have to do anything more," Vazquez-Padin adds.

"Then you need to learn how the signal evolves and take the knowledge you want from the signal. The truth is that the maintenance, in this case, was very easy."

Taking the collaboration to the next level

As well as pushing the dial on biosensors, Aqualia is also working on the REWAISE collaboration involving four major European utilities to demonstrate anaerobic sewer mining technology.

So, where does it see the partnership with Sentry moving forwards? In short, adding additional probes to the wastewater treatment plant is just the start.

"Aqualia is identifying the next plants for potential biosensor deployment."

"We always think of biosensors being more related to wastewater, but we can see the applicability in protecting our drinking water networks," says Rogalla. "This would mean we can adjust the plants to remove any biodegradable matter, have a safer network, and provide a more precise dosing of disinfectant."

The company sees reducing chemicals anchored to reducing its carbon footprint. With chemical adjustments based on the bioactivity in water, the added data from biosensors could help to adjust control systems better.

Reviewing its 500 strong wastewater treatment plant portfolio, Aqualia is identifying the next plants for potential biosensor deployment.

"In at least 10 large wastewater treatment plants and 10 networks, we have biogrowth in the network that we wish to control better, so we see a rapid deployment there," adds Rogalla.

Biosensors: the expected standard in public bids?

Commenting on new business development, Vazquez-Padin adds that even public water agencies require biosensors to be part of project bids.

"Some water agencies are asking for real-time biomonitoring, either in the sewers or wastewater treatment plants," he says. "This will also give a competitive advantage, to have a better control system to adjust the dimensioning of the plant.

"It's also a strong value proposition to show that the real-time monitoring is from an external company; it's not Aqualia. We plan to use the Sentry data to demonstrate that our technologies are fulfilling the discharge limits – it's a very promising technology for the future."

In conclusion, the way things have always been done in wastewater treatment and a lack of monitoring may not be the way they will be done in the future.

The Aqualia team has a vision: less of the unknown networks but smarter, interconnected infrastructure monitored in real-time. They see waste as a thing of the past, and data integrated into future insights to help operators make better decisions.

As in the case with the Sentry partnership, Biosensors could be the measuring evolution needed to help the team get there. Watch this space.