Singapore takes MBR to next level with Changi 3

Singapore's National Water Agency, PUB, has commissioned Jacobs to design one of the world's largest MBR based water reclamation plants, which will achieve a 90 per cent recovery rate.

One of the world's biggest MBR plants?

Singapore's National Water Agency, PUB, has commissioned Jacobs to design one of the world's first Membrane Bioreactor (MBR) based water reclamation plants.

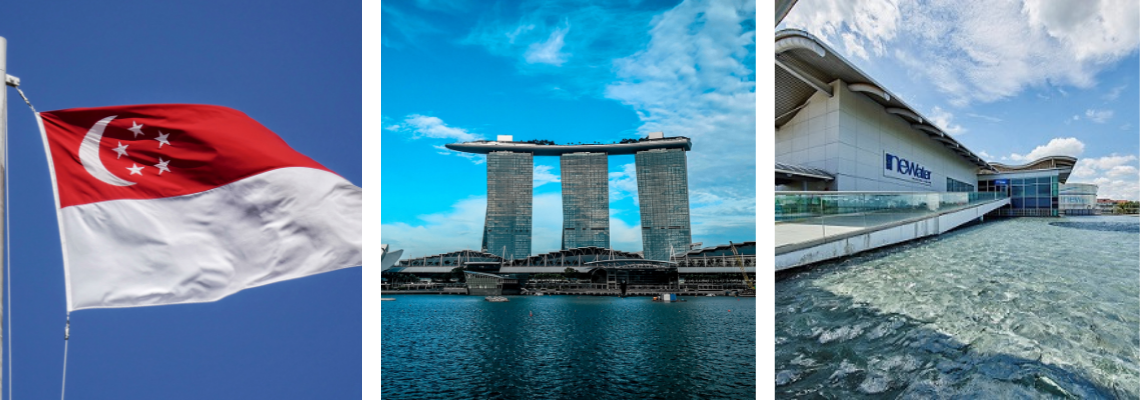

The Changi NEWater Factory 3 (CNF3) will be the third NEWater plant to be located at the Changi Water Reclamation Plant (WRP).

Following planned extensions to the Changi WRP, the plant will use reverse osmosis (RO) and ultraviolet light (UV) disinfection to treat effluent taken indirectly from the new MBR system.

The CBF3 will have a capacity of 227,300 m3/day, equal to 50 million gallons per day (mgd) and will incorporate the WFI Group's ROTEC proprietary RO flow reversal (FR-RO) technology into the design of the RO system.

This will see the recovery rate increase by 15 per cent, to an overall 90 per cent recovery rate.

"Using a holistic, integrated approach not only helps Singapore address its water needs but offers possible solutions for other countries around the world facing similar water security challenges," said Steve Demetriou, chief executive officer of Jacobs.

Global Water Intelligence (GWI) reported that Wang & EF Tan Associates was awarded a S$4,800 consultancy contract to carry out a topographical survey in connection with the project.

The contract to provide professional engineering services to assist with the development of the plant was awarded to CH2M Hill Singapore, part of Jacobs, for S$16,452,888 ($12.2 million).

Singapore's water mission

Incorporated into Tuas Water Reclamation Plant, CNF3 will become one of the world's largest MBR plants.

Otherwise known as the Tuas Nexus, it will treat 650,000 m3/day (143 mgd).

The Tuas WRP will receive used water flows from the western part of Singapore by gravity via two separate deep tunnels – a tunnel to convey domestic used water and another to convey high-strength industrial used water.

These two sources of used water will be treated separately and will see it treat as industrial used water at a rate of 150,000m3/day (33mgd).

Singapore is betting on harnessing the synergies of the-water-energy-waste nexus with the construction of an integrated waste management facility and a water reclamation plant.

Part of the Singapore Green Plan’s vision of a circular economy and Zero Waste Nation, Tuas Nexus is expected to become fully operational by 2032.

Investing in circularity

The partnership with Jacobs follows Singapore government’s announcement to invest $200 million to drive new initiatives in water technologies and resource circularity.

The government is allocating S$220 million (US$161.5m) under the Research, Innovation and Enterprise 2025 Urban Solutions & Sustainability (USS) domain.

In total, S$87 (US$63.8m) million is being allocated to support three water technology focus areas:

- Desalination and water reuse

- Used water treatment

- Waste reduction & resource recovery.

Related content

- 4 developments to watch in Singapore

- Singapore invests $200m to drive desalination efficiency & resource circularity

- ‘It was a different world!’ MBR godfather prof Yamamoto on open sourcing his innovation

Share your water technology stories with us

Do you have an innovation, research results or an other interesting topic you would like to share with the international water technology industry? The Aquatech website and social media channels are a great platform to showcase your stories!

Please contact our Sr Brand Marketing Manager Annelie Koomen.

Are you an Aquatech exhibitor?

Make sure you add your latest press releases to your Company Profile in the Exhibitor Portal for free exposure.

We promise never to send you spam and you can unsubscribe at any time!