30 technologies helping to reach Net-Zero

An ambitious pledge

The carbon reduction race is on. In less than eight years, UK water companies will have to meet targets to become “net-zero.”

But what does net zero mean?

Ahead of the government’s 2050 targets, water utilities have collectively pledged to save the emissions of 10 million tonnes of greenhouse gas. To provide context, the industry generates 2.4 million tonnes of CO2e.

Industry body Water UK estimates to reach the 2030 could cost up to £4 billion of capital costs.

With the sector needing to cut millions of tonnes of carbon emissions by the end of the decade, a 10-point roadmap was announced in November, including:

- Protect customers

- Leadership and collaboration

- Urgent action

- Regional focus

- Transparency

- Green jobs and skills

- An economy-wide transition strategy

- Policy support for low carbon operations

- Prioritise Net Zero innovation

- Enable nature-based solutions.

Time is running out

Karyn Georges believes the adoption of new innovations will be fundamental for UK utilities to reach the 2030 target.

The managing director of Isle UK told Aquatech Online: “With the climate and ecological crisis upon us, time is running out to change the way we invest in and manage our water assets.

“Innovators and entrepreneurs have stepped up to the challenge and at Isle we see technologies every day that can help the sector meet its net zero carbon obligations and ambitions…The challenge these companies often have is the time it takes for end users to adopt their solutions, and this can lead to good technologies falling to the wayside.”

At the recent Global Water Summit in Madrid, organised by Global Water Intelligence, Isle presented ’30 technologies for Net Zero’.

In a rapid-fire, interaction session, 30 technologies were presented to help demonstrate what is possible and provoke discussion. It was designed to help “the water sector accelerate their uptake so that it can achieve net zero carbon,” added Georges.

Below we’ve provided a summary list of the solutions presented.

Measuring & monitoring emissions

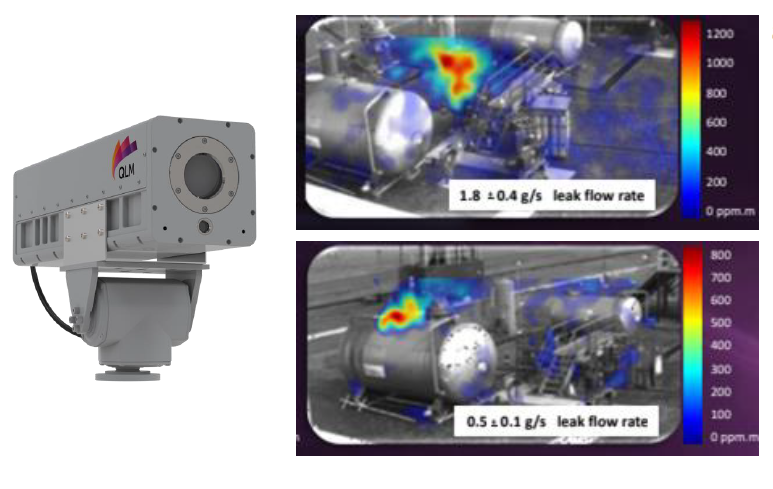

QLM - TDLidar gas sensor

Who: QLM

What: TDLidar gas sensor: single-photon LiDAR gas imaging for continuous autonomous industrial gas monitoring. The “small lightweight” device provides continuous monitoring for fugitive emissions.

USP: Gives site operators live information on gas emissions and leaks so they can plan to reduce them.

Technology ready level: 8/9

Origin country: UK

Aeromon - Airborne emissions monitoring and reporting

Who: Aeromon

What: A 20 parameter sensor that is mounted to a drone that provides real-time data analysis using cloud service and visualised using a choropleth map.

USP: It allows for easy access to difficult locations and leak detection.

Technology ready level: 9/9

Origin country: Finland

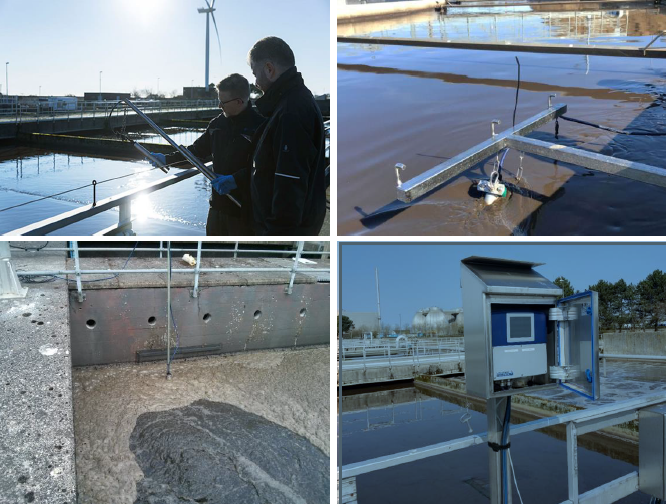

Unisense Environment - N2O Monitor

Who: Unisense Environment

What: N20 Monitor: An online process sensor that can measure dissolved nitrous oxide in real-time. Currently, its technology is used in 200 wastewater treatment plants and has a reduction of CO2-Footprint of up to 80 per cent. A two-year monitoring project of 10 plants in DK established a new emission factor.

USP: Enables the development of new process controls.

Technology ready level: 9/9

Origin country: Denmark

Reducing & controlling operational emissions

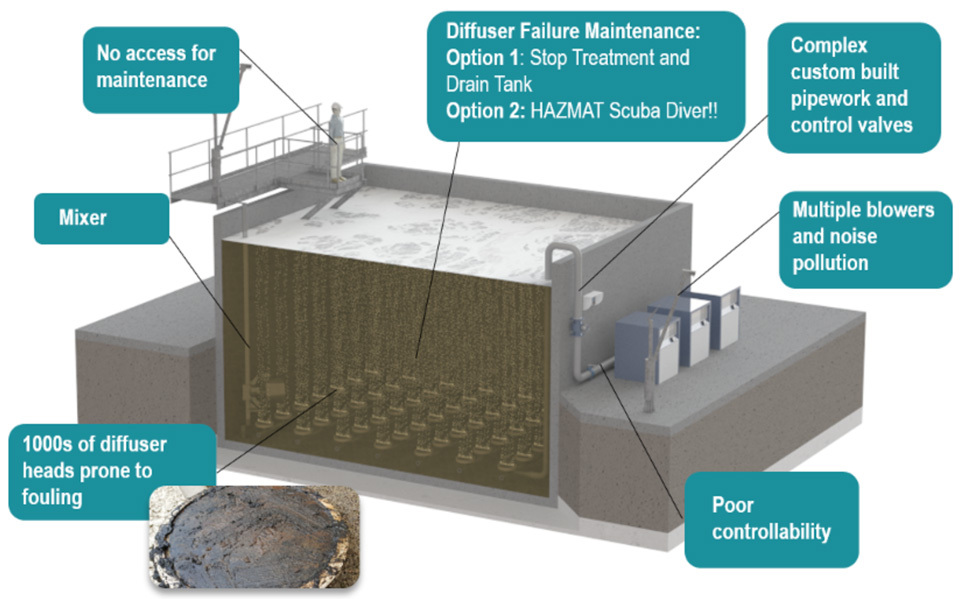

VorTech - Vortex Power Aerator

Who: VorTech

What: Vortex Power Aerator: A high-efficiency, easy to use, low-cost oxygen transfer and mixing aerator. They system features a simultaneous DO monitoring and power cut off when target levels are met.

USP: Up to 20 per cent of the power input is recovered by the systems Annular Jet Turbine and returned to the pump.

Technology ready level: 9/9

Origin country: Ireland

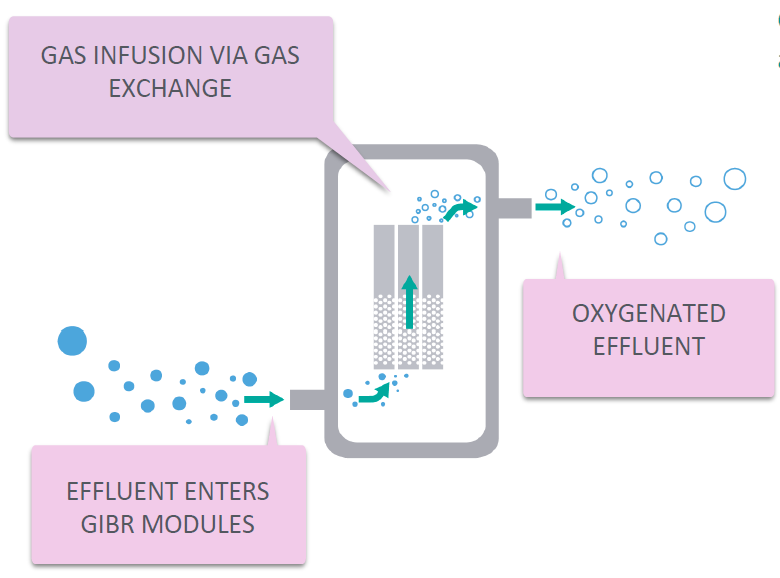

Prosper - Gas inFusion

Who: Prosper

What: A gas infusion biological reactor (GIBR) to meet BOD and COD requirements that has energy savings of up to 85 per cent. It works by wastewater entering the reactor where dissolved O2 is passed into the reactor via a bubbleless transfer with a O2 transfer efficiency of 93 per cent.

USP: It can achieve O2 saturation of over 200 mg/l.

Technology ready level: 7/9

Origin country: US

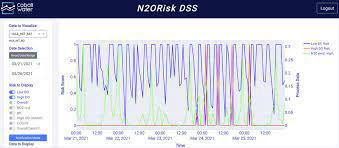

Cobalt Water Global - N2ORisk DSS

Who: Cobalt Water Global

What: The N2ORisk DSS Uses artificial intelligence (AI) and machine learning to determine risk of producing N2O at wastewater treatment works and identifies control strategies to reduce the. The model inputs are operational/water quality data from the wastewater treatment works SCADA system.

USP: Does not require calibration or expensive measurement campaigns.

Technology ready level: 8/9

Origin country: US

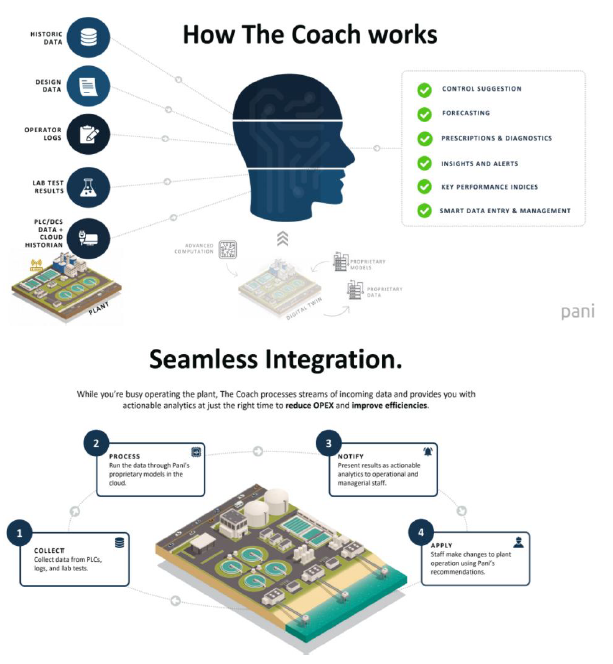

pani – AI Coach

Who: pani

What: AI Coach: A cloud-based machine learning platform for process optimisation of water, wastewater, and desalination plants. The solution collects data across the treatment plant (e.g., PLC/DCS, SCADA, LIMS) to provide real-time, proactive operating instructions to minimise energy and chemical consumption, increase equipment life, and mitigate plant downtime.

USP: Provides Feedback on actions to be undertaken to optimise plant performance.

Technology ready level: 9/9

Origin country: Canada

Typhoon Treatment Systems – UV LED

Who: Typhoon Treatment Systems

What: A ultra-efficient disinfection system using LEDs. Its LED UV system offers a viable non-toxic alternative to traditional Hg lamps systems and can be used to treat COVID-19 and provide safe drinking water.

USP: Large reactor able to treat 750 m3/hour

Technology ready level: 9/9

Origin country: United Kingdom

Renewable energy generation using existing assets

Inpipe Energy

Who: Inpipe energy

What: In-PRV: Electricity generation from pressure reducing valves, the In-PRV® system converts wasted pressure into electrical energy for reuse, emergency backup and even sale. The first installation was at Hillsboro Stadium in Oregon.

USP: In-PRV has energy savings of 200,000 kWh/yr, project life: $1.1 million.

Technology ready level: 9/9

Origin country: US

dph Solarfaltdach Horizon – HORIZON

Who: dph Solarfaltdach Horizon

What: HORIZON: a retractable solar roofing for treatment plants that allows treatment plants to increase self-sufficiency to up to 50 per cent on average. It is retractable to allow for crane access to below assets and during severe weather. The Minimum size of install is 1,100 m2.

USP: Improves plant operation with reduced algal growth, reduced UV radiation and heat

Technology ready level: 9/9

Origin country: Switzerland

Cryo Pur – Cryo Fuel

Who: Cryo Pur

What: Cryo Fuel is a cryogenic transformation of biogas to bio-LNG and liquid CO2 based on cryogenic upgrading of biogas, i.e., frosting and defrosting of CO2 between -90°C and -120°C to separate it from methane. Cryo Pur’s process has a low electricity consumption and uses minimal consumables (only activated carbon).

USP: Heat recovery applied to the refrigeration system can cover up to 100 per cent of the WWTP’s AD heating requirement.

Technology ready level: 9/9

Origin country: France

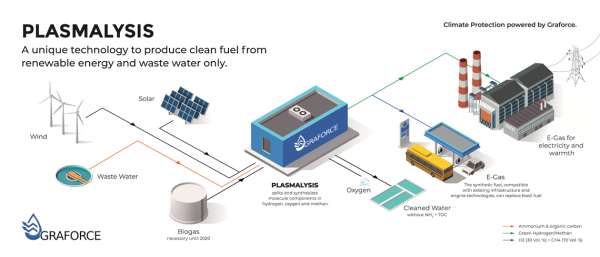

Graforce Hydro – Plasmalysis

Who: Graforce Hydro

What: Plasmalysis is a plasmalyser technology for wastewater, Methane & CO2. Due to its lower binding energy splitting ammonia from wastewater, it allows a 50 per cent cutback of electrical energy consumption per unit hydrogen. Mixing hydrogen with biogas produces HCNG, which can be used as fuel in natural gas vehicles and in block heating and gas power plants with only purified water and oxygen remain as waste products.

USP: COD reduction can be observed.

Technology ready level: 8/9

Origin country: Germany

Reducing fugitive emissions - GHG removal and capture

Elioquo – EloVac

Who: Eliquo

What: EloVac is a vacuum degassing system with phosphate precipitation. It works when a vacuum captures biogas from digested sludge before it is diluted with air, increasing energy recovery, and preventing the emission of methane to the atmosphere.

USP: With EloVac, magnesium chloride is dosed directly into the reactor tank, providing simultaneous phosphate precipitation.

Technology ready level: 8/9

Origin country: Netherlands

bluemethane – Methane capture from water

Who: bluemethane

What: Methane capture from water is a technology to sense, capture and monetise methane emissions from water. It captures and profitably uses methane emissions from water, enabling up to 660mt C02e to be captured when deployed at scale. It features a passive/static principle to capture dissolved methane to make it net energy positive. Suitable for methane concentrations >1g/m3 with methane captured using closed loop circuit.

USP: Captured methane used as a new source of energy and a modular design to treat up to 50 m3/s.

Technology ready level: 6/9

Origin country: United Kingdom

Four-E Systems – GasFrak

Who: Four-E Systems

What: GasFrak is a selective degassing of methane in a biogas plant with minimal maintenance, no chemicals, and wide applications for gas, municipal and industrial. Its technology enables a gain of additional methane of 87 per cent.

USP: Low energy consumption of c.0.018kWh/m3.

Technology ready level: 9/9

Origin country: Germany

Reducing fugitive emissions - Novel, low carbon treatment solutions

Microvi – MNE Platform

Who: Microvi

What: MNE Platform is a microbial carrier for efficient, targeted pollutant removal across water and wastewater. It uses a high density of single, specifically selected, highly efficient organisms that are retained and protected in a biocatalyst composite. Biocatalysts are selected for unique needs including nitrification, denitrification, BOD or COD removal, phosphorus removal and for new and emerging pollutants. It has a small footprint, virtually no waste production, reduced process emissions potential, lower energy costs, increased resilience to influent changes and increased energy production.

USP: Can be integrated within existing processes to intensify performance increasing capacity and/or effluent quality.

Technology ready level: 9/9

Origin country: US

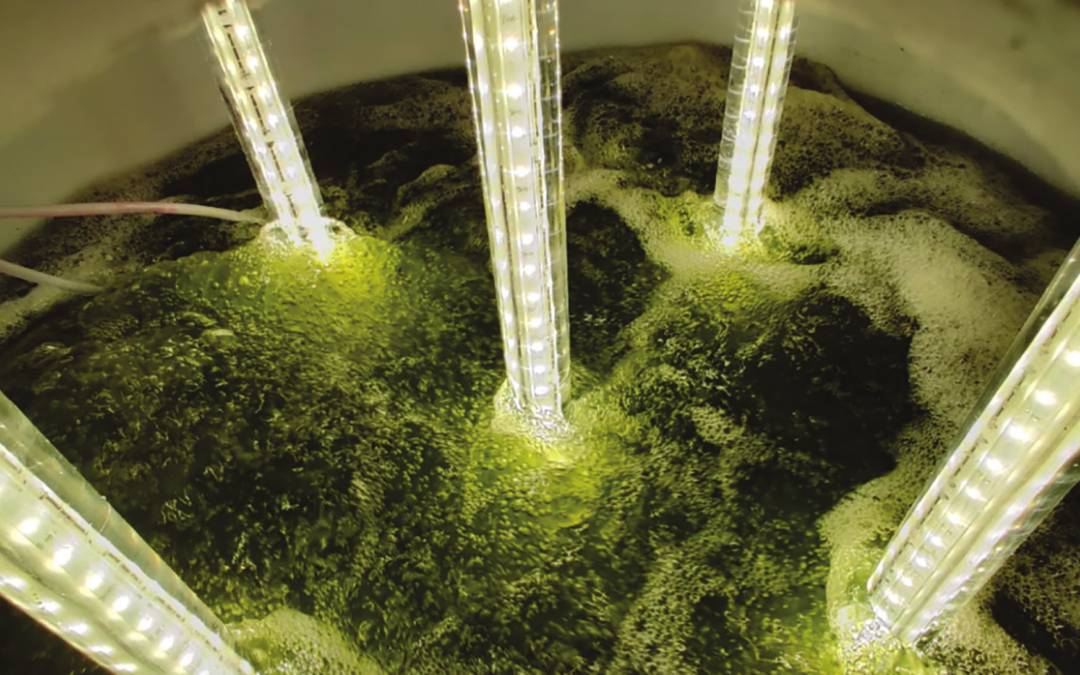

I-PHYC Industrial Phycology – Algal Reactor

Who: I-PHYC Industrial Phycology

What: Algal Reactor is a novel biological system to remove nutrients, COD, and emerging pollutants with the algae consuming CO2 for growth. The algal biomass that is produced can be monetised in a number of ways, including biogas production.

USP: Algae biomass has numerous applications

Technology ready level: 8/9

Origin country: United Kingdom

Innoqua – Daphina Filter

Who: Innoqua

What: Daphina Filter works using a combination of filtration using zooplankton, and biological nutrient removal using biofilms. The system can be used in place of other tertiary wastewater treatment processes while offering a 75 – 90 per cent energy saving.

USP: In Spain, the 1.5 m3/day pilot plant demonstrated removal efficiencies of up to 61 per cent TSS, >30% COD and BOD5, 54 per cent ammonium and 11 per cent total phosphorus.

Technology ready level: 7/9

Origin country: European Union funded project based in France

Bamboo for Life

Who: Bamboo for Life

What: Bamboo for Life is a wastewater treatment solution based on the density of Bamboo’s roots (rhizomes) and their high capacity to allow bacteria to develop and eliminate pollutants. Pre-treated effluent concentrates in the roots of the bamboo which are home to a high population of bacteria.

USP: Can be used to treat industrial and domestic wastewater.

Technology ready level: 9/9

Origin country: France

Infinite Water - Hydroxon

Who: Infinite Water

What: Hydroxon is a catalytic advanced oxidation process for disinfection in drinking water treatment. The system produces hydroxyl radicals that are applicable for different water types and does not require ozone or UV light –both of which are energy intensive processes.

USP: Equipment cost savings up to 50 per cent and operational savings up to 70 per cent.

Technology ready level: 8/10

Origin country: Australia

Redesign of assets

elemental water makers – Elemental Water Source

Who: elemental water makers

What: Elemental Water Source is a solar powered desalination system for water treatment targeted for water scares areas. It can generate up 1,200 m3/day costing $1.30/m3 providing savings of up to 70 per cent on water production expenses. A gravity feed 1,200 m3/day system was able to save 25 tonnes of CO2 per year.

USP: The entire system can be controlled and monitored remotely.

Technology ready level: 9/9

Origin country: Netherlands

Impact-free Water – Wave Powered Desalination

Who: Impact free Water

What: A wave powered seawater desalination, electrical power production and high volume/low pressure seawater supply unit. It works on the seabed anywhere between 500 meters and one kilometre, the pump, using wave power, pushes water through an undersea pipe up to the surface. Once at the surface the water is run through reverse osmosis unit to produce fresh water and a turbine to produce energy.

USP: Multifunctional unit

Technology ready level: 7/9

Origin country: South Africa

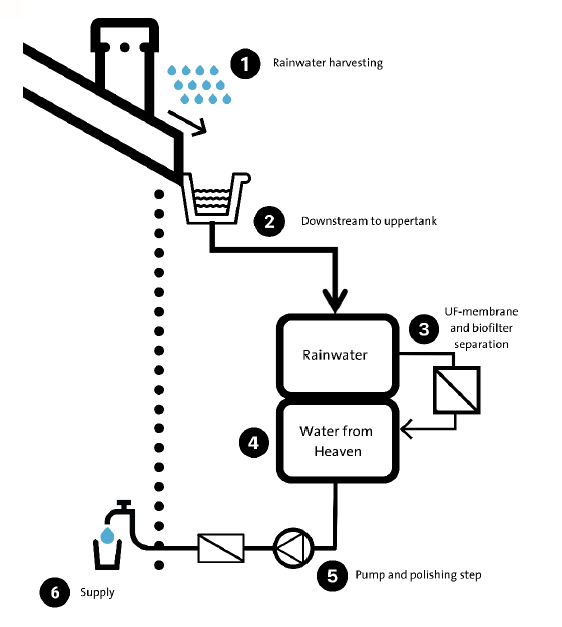

Water from Heaven

Who: Water from Heaven

What: A decentralised, low energy, ultrafiltration rainwater treatment system that harvests rainwater and treats it by gravity through a bioreactor and membrane and stored in tanks for later use. It uses no energy, chemicals or natural gas required for harvesting nor treatment.

USP: No waste stream and requires no power.

Technology ready level: 7/9

Origin country: Netherlands

desah – desah BV

Who: desah

What: The desah BV is a source separation and wastewater treatment system that makes use of vacuum toilets that save 25 per cent water consumption. At its source treatment of wastewater, it uses UASB to generate sludge, biogas and struvite and grey water treatment for local reuse.

USP: Total treatment is 35 m3/d, and its separated system has an 81 per cent lower climate impact on global warming compared to a conventional system.

Technology ready level: 8/9

Origin country: Netherlands

Beneficial by-product reuse

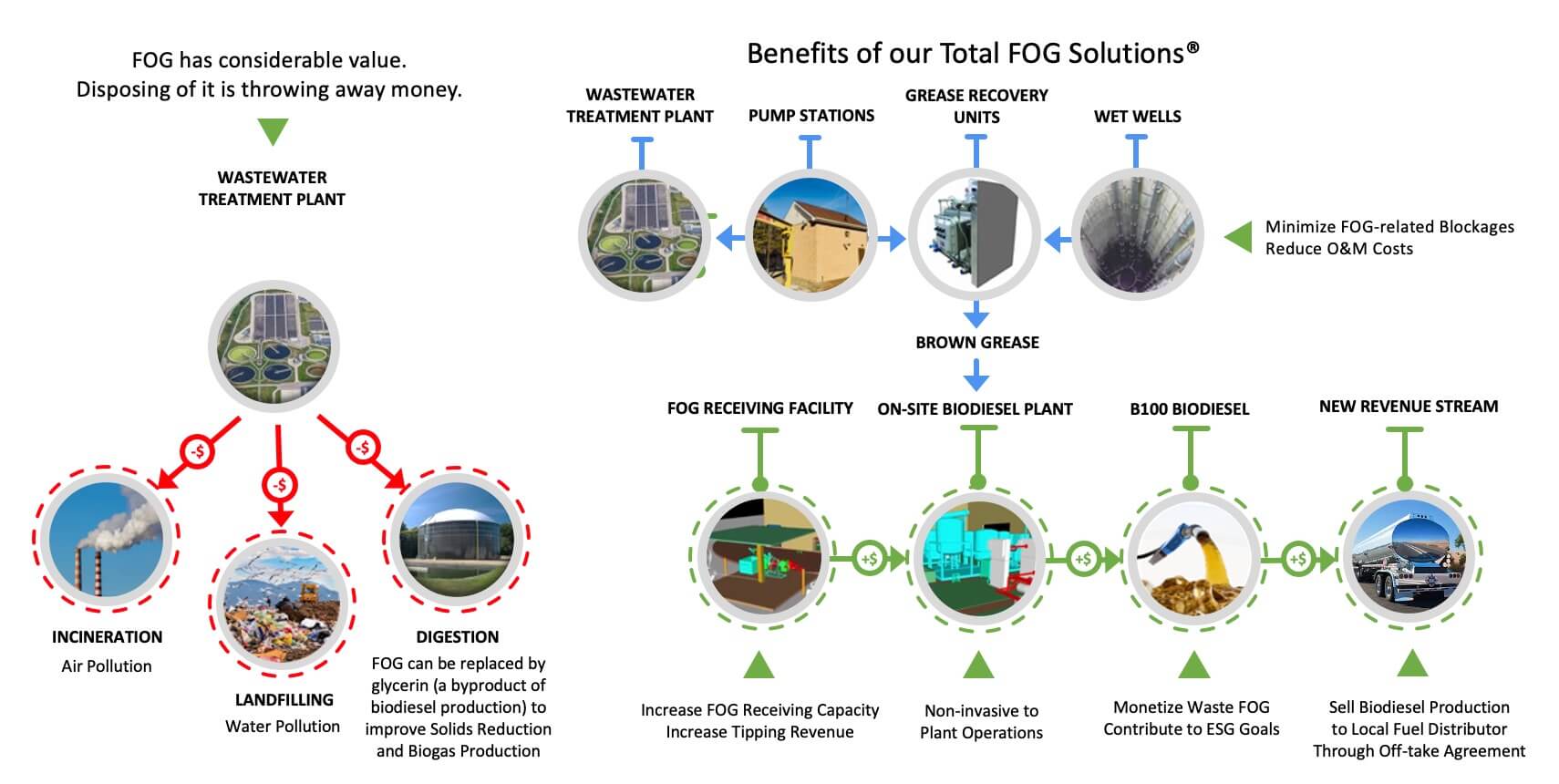

REA – Total FOG Solutions

Who: REA – Resource Recovery Systems

What: Total FOG (fats, oils, and greases) Solutions that turns FOG into biodiesel for reuse. Operated via a continuous reactor system, FOG is received at a facility and processed at its on-site biodiesel plant where it is turned into B100 biodiesel for new revenue options.

USP: Wide potential to supply biodiesel to existing markets in transition.

Technology ready level: 8/9

Origin country: US

Hazer Group – Hazer

Who: Hazer Group

What: Hazer is a low emission hydrogen and synthetic graphite production technology. Carbon content of the natural gas feedstock is captured in the form of solid graphite where Hazer produces ‘clean’ hydrogen.

USP: The hydrogen purity is 99.99 per cent and the synthetic graphite is 80-95 per cent total graphitic content (TGC).

Technology ready level: 7/9

Origin country: Australia

SHARC Energy Systems – Heat Recovery

Who: SHARC Energy Systems

What: SHARC’s wastewater heat recovery system extracts thermal energy from wastewater to provide cost-effective and eco-friendly space conditioning and water heating. Installations have seen up to 700 tonnes a year reduction of CO2.

USP: Can be applied to single properties or at district scale.

Technology ready level: 9/9

Origin country: Canada

CCm Technologies

Who: CCm Technologies

What: CCm Technologies system captures carbon dioxide for reutilisation. By using CO2 from industrial power generation to stabilise a wide variety of materials, CCm creates new fertiliser products with significantly lower than carbon and resource footprint.

USP: CCm fertilisers exceed environmental performance and positively impacting soil fertility.

Technology ready level: 9/9

Origin country: United Kingdom

Organics – Organics Thermal Ammonia Stripper

Who: Organics

What: Organics Thermal Ammonia Stripper (OTAS) removes ammonia from process and wastewater to be recovered as ammonium hydroxide or anhydrous ammonia. The process does not produce sludge and does not require the addition of chemicals for pH or an additional carbon source. OTAS removes up to 98.5 per cent of ammonia, removing the need for additional treatment steps.

USP: The use of OTAS completely avoids the formation of nitrous oxide.

Technology ready level: 9/9

Origin country: United Kingdom

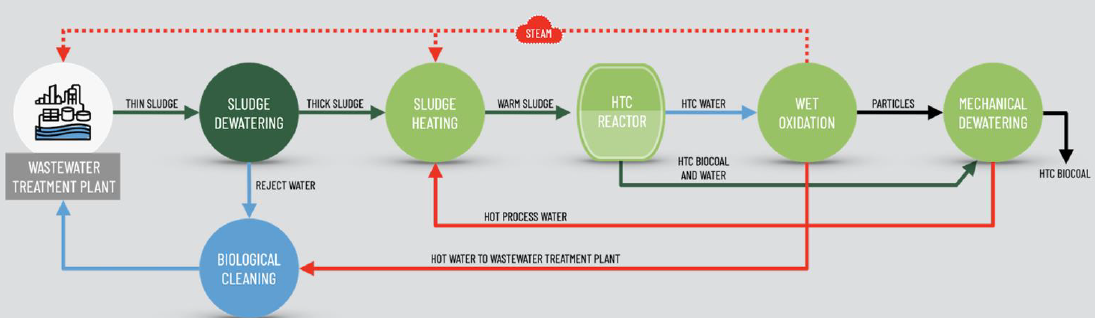

C-Green – OxyPower HTC

Who: C-Green

What: OxyPower HTC converts wet biowaste into solid HTC bio coal. The system combines three technologies hydrothermal carbonisation HTC, wet oxidation & bio-treatment. It has a sludge capacity of 25,000 tons/year converting wet sludge into biochar.

USP: Extremely energy efficient, nutrient recovery, carbon recovery and destroys pathogens.

Technology ready level: 8/9

Origin country: Sweden

Related content

- Route map for net zero water spurs climate action

- Putting reputations on the line in the drive to net zero

- Net zero targets can drive business efficiency, conference delegates told

Loading component...

We promise never to send you spam and you can unsubscribe at any time!