TECH DIVE (pumps): When water’s workhorse gets smarter

With growing environmental pressures, the water sector continues to face pressure to reduce its energy footprint.

What role can improved, smarter and optimised pumps play in helping the sector become more energy efficient? We take a look at the ‘smart pump’ category to look at the different offerings.

Water's energy loss

For a long time, the water sector has had an interesting relationship with energy.

Critical to the energy sector yet also a large consumer of energy, the connection between the two is coming under increasing strain.

An independent report from the IEA found that the water sector consumes four per cent of the world's total global energy, a figure that is expected to double in the next 25 years.

Of this four per cent according to Statista, 42 per cent of the energy is consumed by water-supply networks, 26 per cent by desalination and water re-use technology, 14 per cent by wastewater treatment plants, 13 per cent on water distribution and five per cent on water transfer.

And how is all this water moved around? Pumps. A lot of them.

How much energy does a pump use?

With four per cent of the world's energy being used by the water sector, how much are pumps responsible for?

Certainly a tricky question to answer, with multiple variables that need to be taken into account.

For example, it requires less energy to pump surface water than it does pump to groundwater. The amount of energy it takes to pump water a long distance will be greater than it is over a short distance.

Other variables for pumping include the topography (affecting groundwater recharge), climate, seasonal temperature, and rainfall.

Where water is being pumped also plays a key role. In California, for example, 19 per cent of the state’s electricity consumption is for pumping, treating, collecting, and discharging water and wastewater.

At drinking water plants, the motors required to pump water can account for as much as 80 per cent of the plant's total energy consumption.

Likewise, at wastewater treatment plants, pumps and solids processing take the top spots for energy consumption.

A lack of information

A study carried out by researchers at the University of Texas at Austin in 2017 found that the energy consumed by the US public water supply was the country's primary source for residential, commercial, and municipal users.

It found that energy use associated with the public water supply was 4.1 per cent of the nation’s annual primary energy consumption and 6.1 per cent of national electricity consumption.

“The study found that energy use associated with the public water supply was 4.1 per cent of the nation’s annual primary energy consumption.

Electricity consumption by public drinking water and wastewater utilities for pumping, conveyance, treatment, distribution, and discharge was 56.6 billion kWh, or 11.5 per cent of primary energy and 21.6 per cent of electricity consumption for water end-use.

The British Pump Manufacturers Association (BPMA) has previously said that pumps are the single largest user of electricity within the industry across the European Union, consuming over 300 TWhpa of electricity.

The opportunity

As urban centres strive for resilience, become more sustainable and improve their energy footprint, the drive for smarter cities could relate in a drive for smarter pumps.

Pumps account for up to 40 per cent of industrial energy usage in modern cities, and smart pumps can provide one energy-saving solution to cities looking to convert into smart cities.

“Pumps account for up to 40 per cent of industrial energy usage in modern cities.”

In an article for SmartCitiesDive, Peter Gaydon, director of technical affairs at the Hydraulic Institute, looked into the potential growth of smart pumps for city applications.

"Smart pumps enable decision-makers to collect and share data to better manage the flow of energy needed to meet system demand. This gain in efficiency, driven by the internet of things, aligns with the methodology of smart cities to more effectively manage assets and resources — ultimately leading to the achievement of municipal sustainability goals."

What makes a pump smart?

Aquatech online recently looked at the rise of the smart pump and how it connected to the Internet of Things (IoT) to help utilities and water companies to better visualise data using Big Data, analytics, machine learning algorithms and cognitive intelligence.

Put simply, smart pumps allow users to monitor and provide real-time information on multiple factors about the water passing through them.

Information such as the pump’s health, its performance, pressure, temperature, and the velocity of the water.

Add in the IoT capabilities, utilities and companies handling water can effectively build an interconnected eco-system of smart pumps that are continuously providing data to a central hub.

These pumps are typically a lot more energy efficient than the ones they are replacing, requiring little manual intervention and being able to operate autonomously.

So who are the key players?

Danfoss – High pressure smart pumps

Source: Danfos – High Pressure Smart Pump range

Danish engineering company, Danfoss, has developed its axial piston pump technology that it says features all the advantages of positive displacement pumps to high-pressure applications.

The company said its High Pressure Pumps (HPP) is one its fast-growing divisions seeing its technology grow in diverse markets from reverse osmosis, to gas turbines, to cleaning and humification and firefighting.

“The smart technology we employ enables spare part replacements and repairs via predictive maintenance at exactly the right time.”

Its PAHT and PAHT G pumps for ultra-pure water applications can handle flows ranging from 0.7 to 354 l/min (0.2 to 93.5 gpm) and pressures up to 160 barg (2,321 psig).

Kaspars Damis, head of marketing, High Pressure Pumps, Danfoss Climate Solutions, told Aquatech Online: "Danfoss High Pressure smart pumps are enabling our customers to achieve more with less as high pressure pump condition monitoring and future digital solutions are making it possible to run the pumps at maximum efficiency.

"The smart technology we employ also enables spare part replacements and repairs via predictive maintenance at exactly the right time, reducing waste by replacing parts based on calculated average service intervals.”

Danfoss says its high pressure smart pumps are able to run high pressure equipment at maximum efficiency while also reducing energy consumption and CO2 emissions, especially in energy intensive desalination plants.

“After all, the greenest energy is the energy we don't use. It is also the most cost efficient,” added Damis.

"Our smart technology, which defines the predictive maintenance schedules also allows us to avoid unplanned downtime which is especially important in critical infrastructure like a desalination plant as water is an essential resource for the community.”

Xylem - wastewater & residential

Water solutions company Xylem has a selection of smart pump offerings for both residential applications and for wastewater.

Source: Xlyem – Lowara Smart Pump range

Its Lowara Smart Pump range features pre-programmed packages designed for “easy cost-effective installation”. The pumps are all connected via IoT and allow users to have total control over the water passing through them.

Users can control constant pressure and match a system curve. The eco-system also allows for the pumps to stop at zero demand, water failure, protection against dry running and also features sensors to monitor overheating and voltage.

Its smart wastewater pump called the Flygt Concertor offers energy savings of 70 per cent compared to a conventional pump, Xylem said.

Source: Xlyem – Flygt Concertor

Klas Carlsson, senior manager of integrated systems and Stephen Clark, global product manager of applied water systems at Xylem, said the pump features integrated technology such as power electronics including edge computing capabilities.

The built-in intelligence “allows them to continuously operate at optimal energy consumption levels and activate self-cleaning functions when needed”.

Speaking to Aquatech Online, Carlsson said the smart water pumps combine three elements and that “it’s not about individual components. It’s about a great team of three perfectly concerted elements”.

Grundfos: Smart dosing & circulating

Source: Grundfos – Digital Dosing Smart Pump

Grundfos has two notable developments. First, its Smart Digital Dosing pumps for high precision dosing of chemicals, enabling advanced control of process and integration with system control.

It features a max flow of 940 I/h and a head max of 16 bar.

Source: Grundfos – UPS2

Second is its light commercial heating circulator, the UPS2 25-80, a circulator pump with permanent-magnet motor (ECM technology) and continuously variable speed control for circulation of clean heating water.

Grundfos says this pump features integrated differential-pressure control enabling adjustment of pump performance to the actual system requirement.

It also has a motor based on permanent-magnet/compact rotor technology and the pumps are energy-optimised and comply with the requirements of the energy-using-products (EuP) directive.

The UPS2 also requires less power consumption, and reduces noise from thermostatic valves and similar fittings and improve the control of the system, according to the comapny.

KSB – the smart factory

Source: KSB – KSB Guard

Source: KSB – KSB Guard

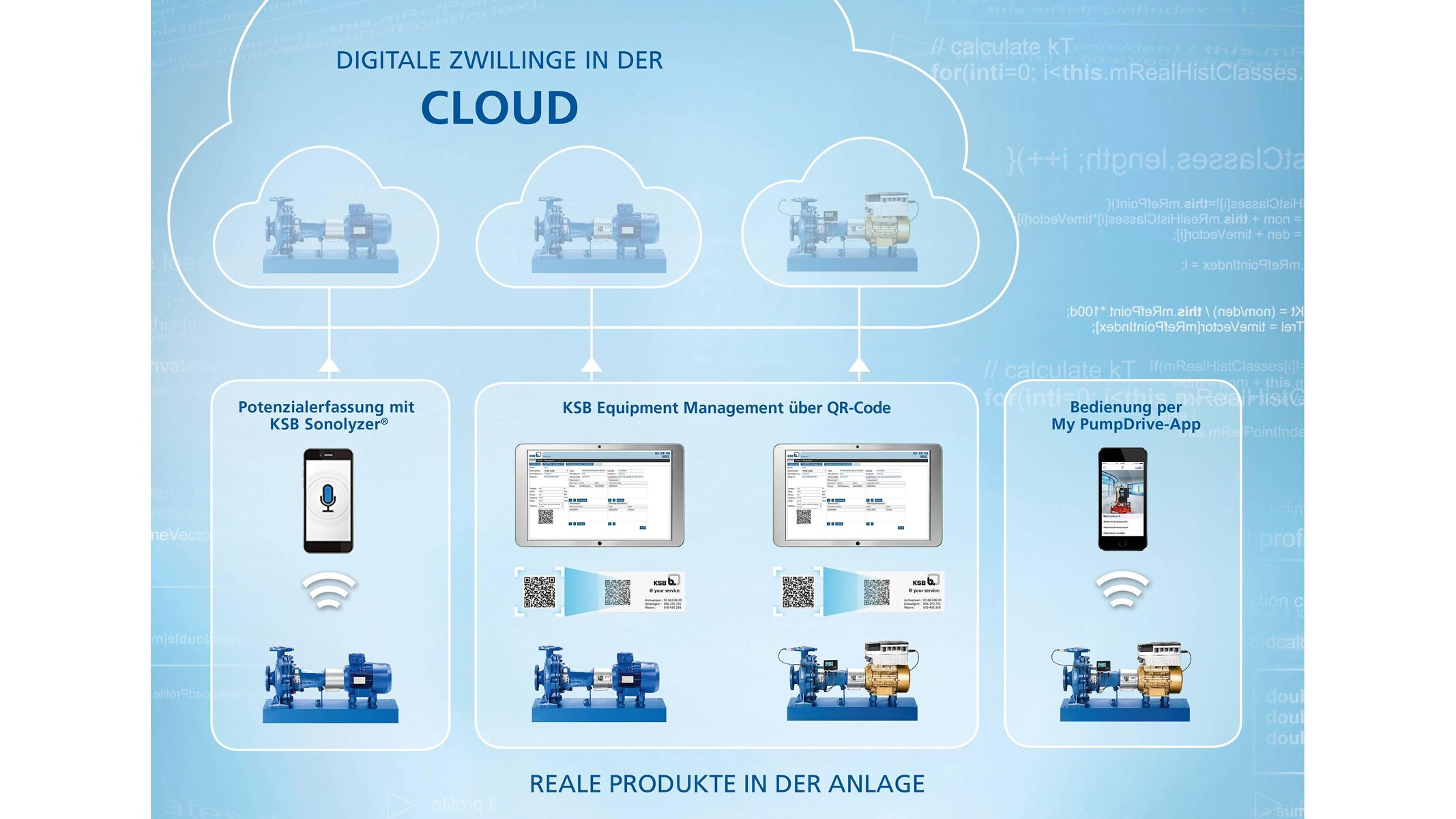

German company KSB has developed the smart factory – a place where KSB aims to bring all of its products in line with current IoT developments.

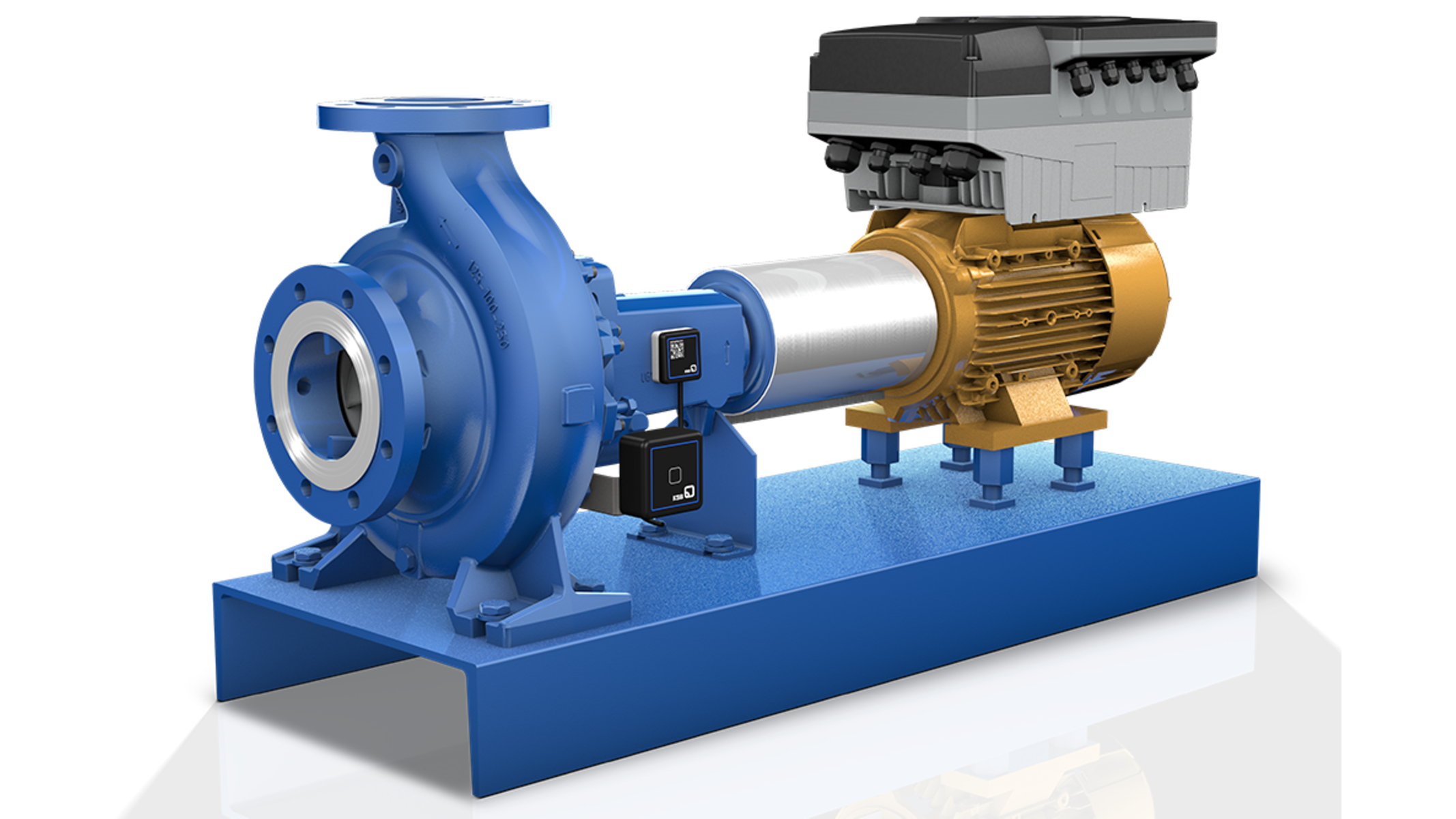

One of the products to come out of the smart factory is the KSB Guard, a cloud solution for remote monitoring of pump populations.

KSB Guard is its sensor unit, which is installed directly on the pump and records the pump vibration and temperature data.

The transmission and battery unit supplies energy to the sensor unit and transfers the measurement data to the connection port. Maintaining the highest security standards, the connection port transfers data to KSB Cloud via the mobile phone network.

Pump data and additional information can be evaluated simply and easily via the KSB Guard app or web portal. This facilitates the scheduling of maintenance work and the targeted use of resources.

Source: KSB – Pump Drive

Source: KSB – Pump Drive

Furthermore, the PumpDrive is its flagship smart pump and has a variable speed system. This continually adjusts the pump speed and, hence, pump output in line with actual system demand, ensuring that the pump operates as efficiently and reliably as possible.

It has a built-in wireless module, PumpDrive and can be controlled via Bluetooth, meaning a smartphone can act as a “remote control”, with all of the data and information available in the app.

Related content

- Tech dive: the rise of the smart pump

- Tech dive: why smart water meters are getting smarter

- STech dive: the future of point of use systems

https://www.ksb.com/en-es/company/press-releases/the-smart-factory-we-are-ready-for-industry

https://sgp.fas.org/crs/misc/R43200.pdf

https://www.iea.org/reports/water-energy-nexus

https://www.aquatechtrade.com/news/water-treatment/tech-dive-rise-of-the-smart-pump/#

https://benjaminellis.org/2012/02/09/smart-pump-warm-house-less-power/

https://www.smartcitiesdive.com/news/smart-pumps-are-key-for-more-sustainable-cities/581841/

https://empoweringpumps.com/schneider-electric-smart-pumping-benefits-barriers/

Loading component...

We promise never to send you spam and you can unsubscribe at any time!