Breakthrough for anti-fouling graphene membrane technology

Singapore-based Memsift Innovations has entered into a technology transfer agreement with Ngee Ann Polytechnic for its anti-fouling graphene membrane technology, which has the potential to be used in harsh industrial environments.

Anti-fouling graphene membranes

The membrane technology has been developed following a decade of research at Ngee Ann Polytechnic in Singapore.

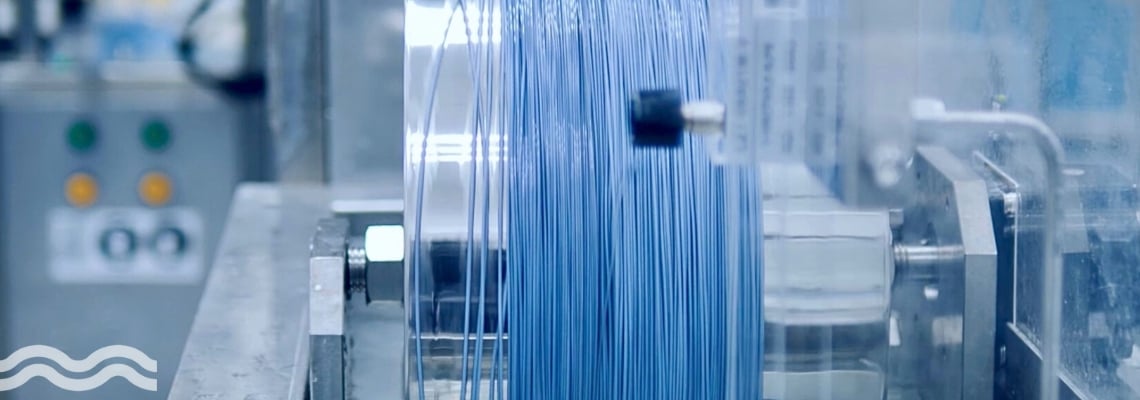

The technology features graphene oxide-based hollow fibre ultrafiltration and nanofiltration membranes that utilise a graphene oxide-block copolymer composite renowned for its exceptional chemical and thermal stability.

The membranes' surface chemistry forms a protective water layer that effectively prevents fouling, making them ideal for use in harsh industrial environments.

It has the added advantage of reducing energy consumption and lasting longer than traditional membrane technologies.

Nanofiltration technology

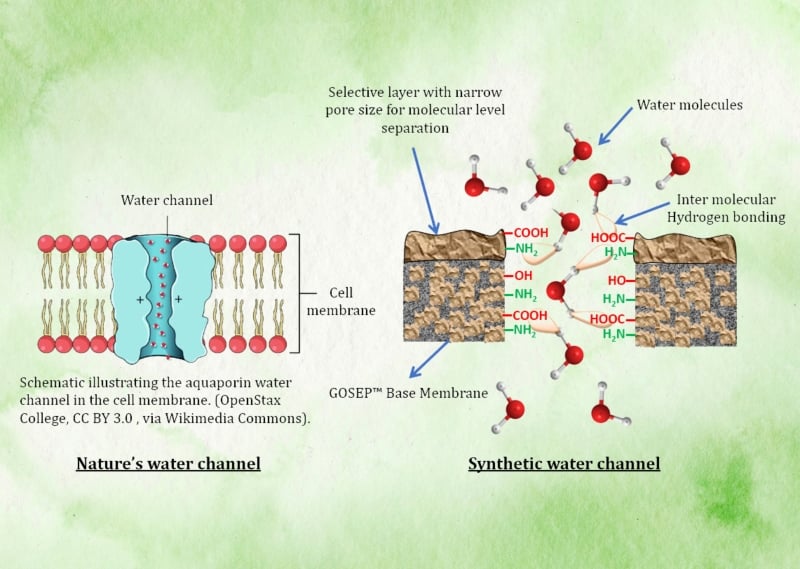

The nanofiltration technology employs a robust single-layer modified graphene oxide membrane with synthetic water channels, enhancing selectivity and permeability. This enables efficient molecular-level separation and differentiation between monovalent and multivalent ions.

All of these technological advances offer improved performance for a broad range of industries, including textiles, agriculture, food and beverage, pharmaceuticals, pulp and paper, chemicals, microelectronics, semiconductors, and mining.

Adding to a portfolio of solutions

The acquisition of the anti-fouling graphene membrane technology has added to Memsift Innovations' portfolio of solutions designed to treat challenging industrial liquid waste. The company plans to integrate the chemical-resistant hollow fibre nanofiltration technology into its liquid waste solution as a separation and purification unit before its membrane distillation concentration technology, aiding in chemical recovery.

According to Dr J. Antony Prince, founder and CEO of Memsift Innovations, this will close 'the industrial liquid-waste loop'. He told media: "This is a highly anticipated milestone in our journey. The new graphene membrane technology offers several advantages over current state-of-the-art nanofiltration technologies."

He added: "This advancement solidifies our market position in industrial liquid waste treatment and resource recovery, enabling us to provide our customers worldwide with the most advanced and valuable technologies."

Decades of research and development

The technology was developed at Ngee Ann Polytechnic's Centre for Environmental Sustainability (CfES).

Dr Jason Tang, director of the Centre for Environmental Sustainability and chief sustainability officer at Ngee Ann Polytechnic, added, "As a centre driving industry partnerships for green solutions and talent development, we are committed to engineering cutting-edge innovations that positively impact the environment."

The centre, which forms part of the polytechnic's Sustainability Education & Ecosystem Development (SEED) initiative, is committed to forging strong industry partnerships to develop cutting-edge environmental solutions and cultivate a skilled workforce.

Tang added: "The graphene oxide membrane technology we developed is groundbreaking, as it can reduce energy consumption by up to 50 per cent and has a lifespan twice as long as conventional membranes. My team is excited about the potential of this technology to enhance the sustainability of industrial water treatment."

Loading component...

Share your water technology stories with us

Do you have an innovation, research results or an other interesting topic you would like to share with the international water technology industry? The Aquatech website and social media channels are a great platform to showcase your stories!

Please contact our Sr Brand Marketing Manager Annelie Koomen.

Are you an Aquatech exhibitor?

Make sure you add your latest press releases to your Company Profile in the Exhibitor Portal for free exposure.

We promise never to send you spam and you can unsubscribe at any time!