The road to RIKovery: Industrial salt recovery links Germany and China

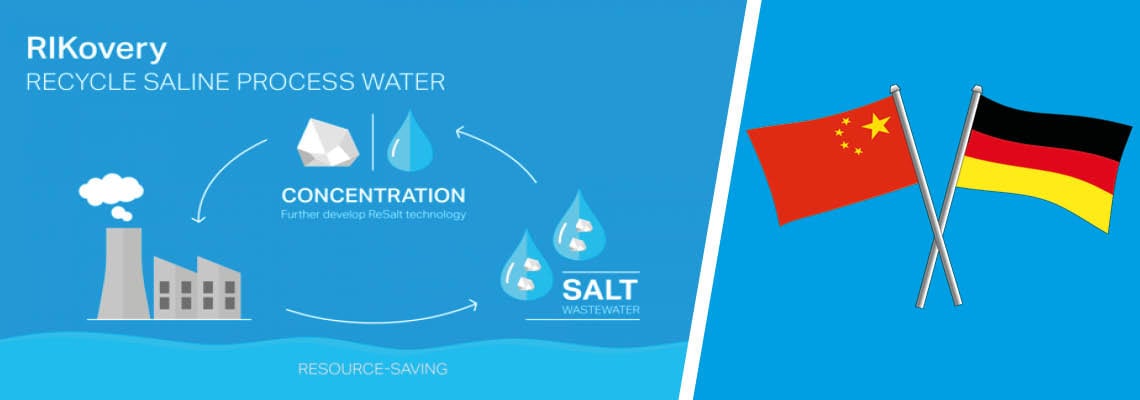

A new research project focused on looking into the treatment of industrially processed water by extracting salt will see Germany work closely with China.

The road to RIKovery

A new research project focused on the extraction of salt from industrial process water is connecting Germany to China.

Funded by the German Federal Ministry of Education and Research, the new RIKovery project will look at how salt-containing industrial water streams can be most effectively used to relieve the growing pressure on natural water resources.

The three-year project will see how salt-containing industrial water can be used not only in internal circular water projects but also as a manner to offset the dependence on natural water resources.

This new initiative follows the ReSalt project, which researched the recovery the sodium chloride from industrial wastewaters and the possibility to recirculate it in chlorine-alkali electrolysis and reusing the purified water.

The need for circular solutions

By 2050, it’s estimated that water stress will affect almost 50 per cent of the world's population.

Research projects such as the RIKovery project and the ReSalt project are designed to help accelerate the use of reuse technologies among industrial manufactures.

The RIKovery project is not just about focusing on water reuse, but also how companies can further reduce their use of raw materials.

"Efficient industrial water management will become a key factor for safe industrial production in the future."

Participating organisations include RWTH Aachen and TH Cologne universities, the Water Technology Center, the Analytical Research Institute for Non-Target Screening (AFIN-TS GmbH), BWS Anlagenbau und Service and Evonik Industries, and German-based polyurethane manufacturer, Covestro AG.

Thomas Track of DECHEMA, said: "Efficient industrial water management will become a key factor for safe industrial production in the future.

"Water-efficient sites are a real locational advantage with a view to resource conservation, but also with a view to droughts favoured by climate change."

Water from polycarbonate production

Covestro AG has production sites based in China, in Krefeld-Uerdingen and Caojing near Shanghai, where industrial saline water recovery plants operate. These plants currently treat and reuse part of the processed water from polycarbonate production.

"We are now taking the next step with RIKovery to use process water in a circular way," said Klaus Schäfer, chief technology officer at Covestro AG.

He added: "We now need to stay on course to use even less water and salt as raw materials for industrial applications in the long term."

The organisation’s participation in the RIKovery project follows suit as other industries look to address their existing water management models.

Cosmetics industry giant L'Oréal recently announced that 100 per cent of the water used in its industrial processes will be recycled and reused in a loop by 2030.

With the 2030 deadline on the UN Sustainable Development Goals quickly approaching, an acceleration of circular reuse of industrial water will be welcomed by many.

Related content

- Cosmetics giants tackle water use to make their business more beautiful

- Nike cuts freshwater use by 30% but admits work to do

- Making 50 litres of water feel like 500

Loading component...

We promise never to send you spam and you can unsubscribe at any time!