MegaVessel membrane envelope innovation

Distributing water evenly across an array of membranes will lead to increased efficiency, OPEX and CAPEX savings and a reduced footprint according to the companies behind the MegaVessel, a reverse osmosis (RO) technology for water treatment.

What is Megavessel and how does it work?

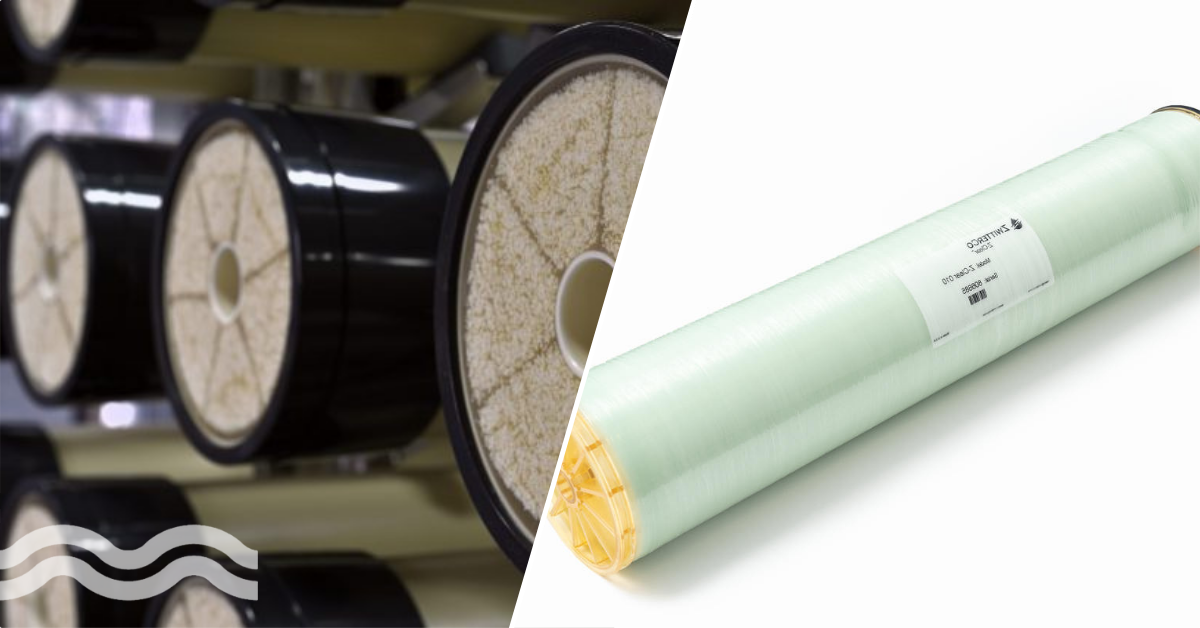

The idea behind Megavessel, was originated by the company of the same. It is being manufactured by Impact Filtration and distributed by H20 Innovation. While many advancements in RO water treatment focus on chemicals and membrane materials, MegaVessel focuses on the physical 'envelope' that houses the membranes.

It has been designed to improve water treatment efficiency by distributing water evenly across a 7x7 array of membranes instead of using the traditional single long array. This has two immediate potential benefits: first, the water pressure is spread evenly, with each membrane receiving exactly the same water flow rate, avoiding the pressure drop common in traditional systems, and second, because it houses seven times more membrane elements, the overall footprint of the system can be reduced by more than a third. The system promotes membrane longevity and increases the overall efficacy.

H20 Innovation's Sergeui Leclerc told Aquatech Online: "The MegaVessel is compatible with various membrane providers, unlike some proprietary systems, which allows for flexibility and potentially cost savings. This means a company can choose a membrane that works best with their system and budget."

Increased water processing and small footprint

The 7x7 design also reduces the need for piping and joints, another factor that leads to a smaller footprint and easier installation than traditional systems, with an associated reduction in in materials and labour costs. Water treatment capacity can be expanded without increasing footprint by stacking MegaVessels. The system also has an advantage when it comes to cleaning compated to traditional RO membrane solutions.

Energy savings can also be realised because the equal distrubution of membranes means the initial pressure can be decreased. MegaVessel features innovative bypass flow technology that optimizes flux distribution and decreases fouling and scaling tendencies.

Applications and current trial phase

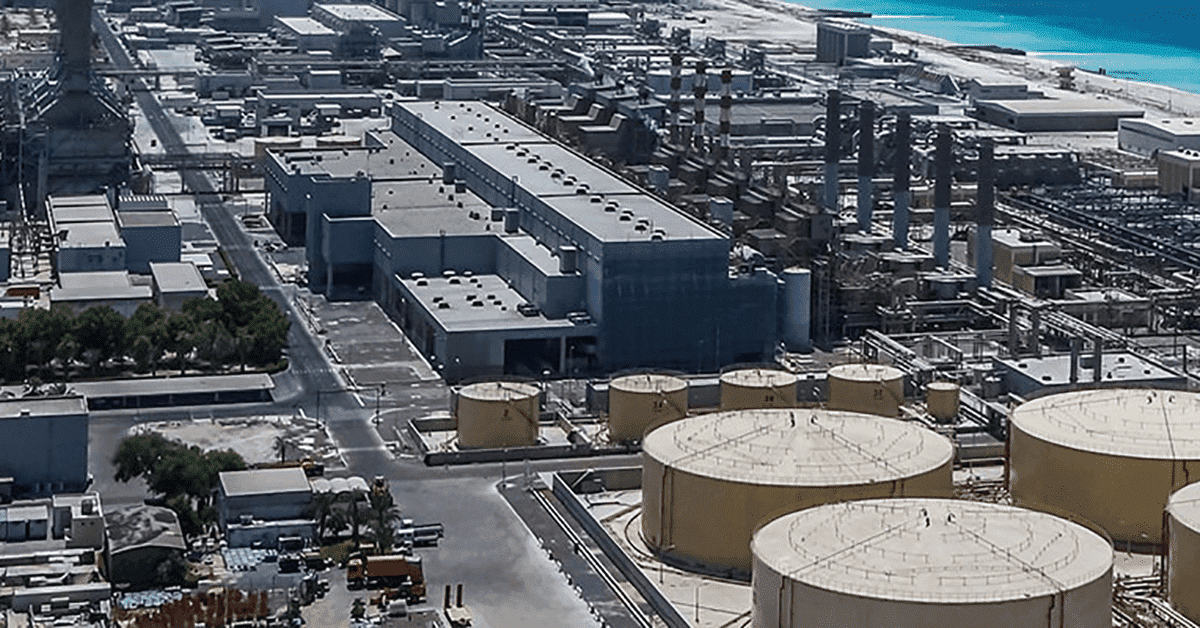

The system can be retrofitted into existing plants or planned into new plants. It can currently treat seawater, brackish water, and soft water and the flow and level of desalination is equal to a standard RO pressure vessel. "Currently, MegaVessel offers the most significant benefits in desalination plants due to the large quantities of water they process, however, they could potentially have an application for wastewater plants as well," Leclerc explained.

It was launched at the IDRA World Summit in Abu Dhabi in December 2024 and trials are currently being conducted at desalination plant in Jeddah, UAE, and a technical trial is running at H20 Innovation's faciltiy in Vista, California, to collect performance data relating to energy and efficiency in real-world conditions.

Leclerc concluded by telling Aquatech Online: "The MegaVessel technology represents a significant advancement in addressing global water scarcity challenges by making desalination and water reuse more efficient, accessible, and environmentally friendly."

He added: "By addressing sustainability differently, the MegaVessel aligns with water positivity and global efforts to mitigate climate change, as well as having a real impact in the water treatment facilities."

Share your water technology stories with us

Do you have an innovation, research results or an other interesting topic you would like to share with the international water technology industry? The Aquatech website and social media channels are a great platform to showcase your stories!

Please contact our Sr Brand Marketing Manager Annelie Koomen.

Are you an Aquatech exhibitor?

Make sure you add your latest press releases to your Company Profile in the Exhibitor Portal for free exposure.

We promise never to send you spam and you can unsubscribe at any time!