Durban unites water reuse & desalination with Remixwater

Combining the best of both processes

Both desalination and water reuse are often pitched as tools for water utilities to provide stable water sources in increasing times of scarcity.

The former takes the salt out of seawater to produce drinking water; the other cleans up wastewater before putting it back into aquifers or reservoirs (indirect reuse), or piping it directly into the water supply network (direct potable reuse).

Yet what about a solution that combines the best of both processes? Not only that but the solution uses 30 percent less energy and with a reduced brine disposal at the end. Sound too good to be true?

Well a collaboration between Japanese engineers and the City of Durban in South Africa have been working on an answer.

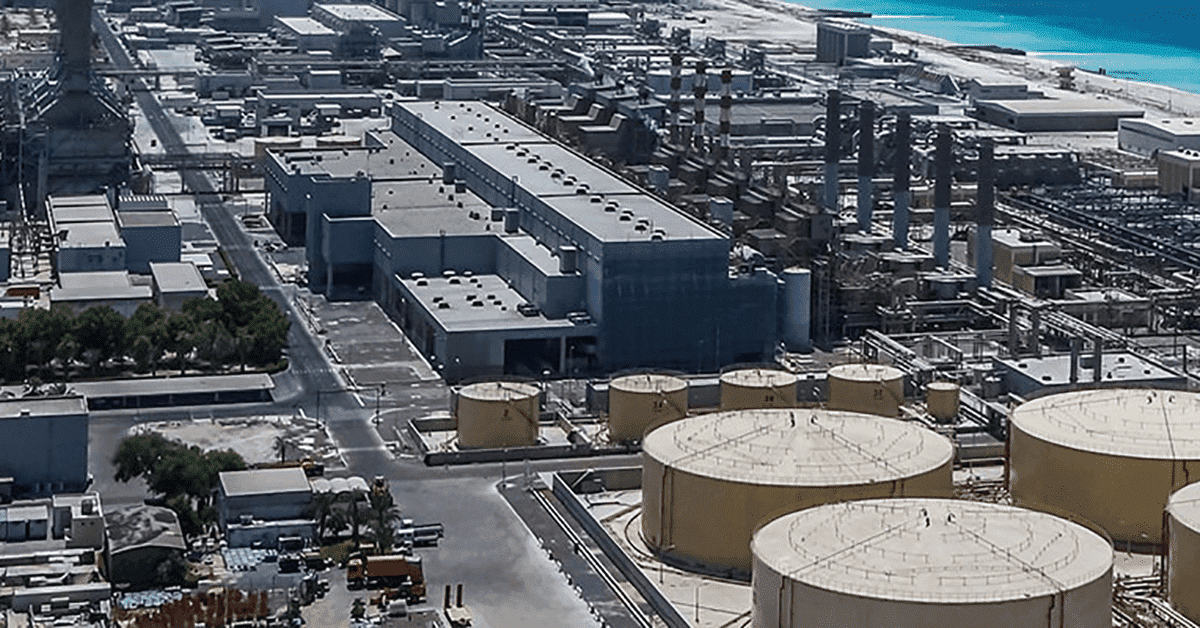

eThekwini Metropolitan Municipality, known as the City of Durban, has been trialling the system known as RemixWater and has now moved forward with full operation.

The system was commissioned and delivered by New Energy and Industrial Technology Development Organisation (NEDO) together with Japanese engineering company, Hitachi, as the contractor.

How does the technology work?

The four-year project started back in November 2016, based on a feasibility study conducted a year earlier.

It ties in with an ‘Outflow Strategy’ from the eThekwini Municipality to investigate several direct and indirect reuse options, including using treated water for environmental water requirements.

Hitachi designed, constructed and has been operating the RemixWater integrated system.

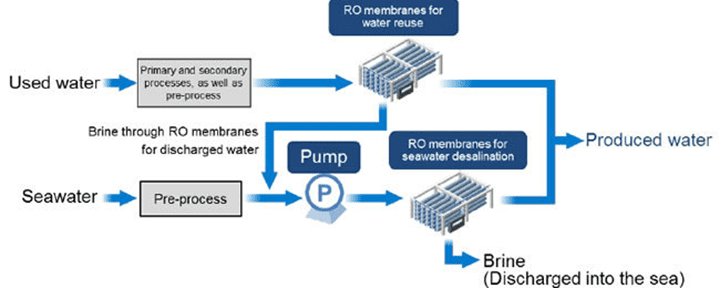

After wastewater is treated, the processed effluent is used to dilute seawater before desalination takes place.

By diluting the seawater, in theory, it means less pressure and energy are needed to take the salt out and high pressure pumps can instead be switched to medium pressure pumps.

As a result, CETO said that power consumption can be cut by at least 30 per cent, compared to existing seawater reverse osmosis (SWRO) desalination systems. This is based on converting 100,000 m3/day at 3.5 per cent seawater salinity.

Brine benefits

As well as the energy saving, the Japanese companies believe RemixWater can also provide benefits when it comes to the disposal of brine.

Brine disposal and management has been put under the spotlight following a UN-backed paper calling the situation a “salty dilemma” in which 142 million cubic metres of hypersaline brine are estimated to be put into the oceans daily.

As the Japanese solution treats diluted seawater, in turn it means the water being discharged will have the “same concentrations as seawater, thereby minimising the effects on the marine environment”.

In short: a less salty by-product to be put back into the oceans.

A novel multi-barrier solution

Leon Awerbuch from International Desalination Consultancy Associates believes the process has the potential to lower energy consumption but that disinfection needs to be considered.

“The challenge is that RemixWater uses the reject concentrate of BWRO (brackish water reverse osmosis), which still has all the pathogens, so it is depending on the SWRO membranes to do the disinfection,” he said.

At the International Desalination Association (IDA) World Congress in Dubai Awerbuch presented his concept: “Novel multi-barrier solution to one water combining municipal water reuse with seawater desalination.”

In the paper Awerbuch recommended such “hybrid combinations” should be tested across many SWRO or thermal distillation plants found in the Gulf GCC region.

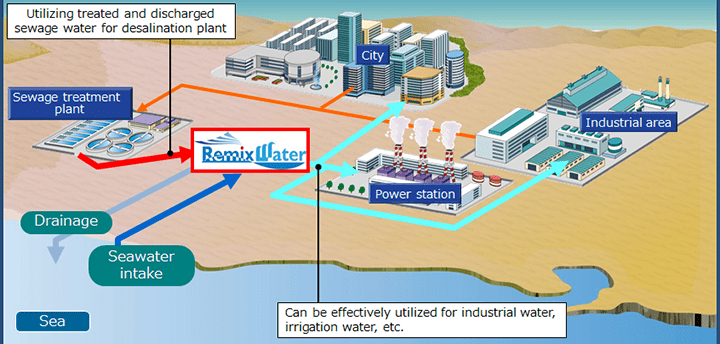

In his outlined process, the permeate of brackish BWRO is used to dilute inlet seawater and the concentrate of BWRO is sterilised in a thermal process, producing direct or indirect potable reuse of treated sewage effluent (TSE).

He suggested that by investing in pipelines to connect wastewater treatment plants to desalination plants, this could take advantage of the “valuable” water for reuse.

“One other aspect is critical to the implementation of the novel processes: the seasonal availability of treated municipal sewerage effluent (TSE),” added Awerbuch. “Typically, TSE is used for irrigation and therefore in summer can consume significant portion but in winter due to reduce evaporation at least 50 per cent of TSE is sent to the sea.”

Related content

Share your water technology stories with us

Do you have an innovation, research results or an other interesting topic you would like to share with the international water technology industry? The Aquatech website and social media channels are a great platform to showcase your stories!

Please contact our Sr Brand Marketing Manager Annelie Koomen.

Are you an Aquatech exhibitor?

Make sure you add your latest press releases to your Company Profile in the Exhibitor Portal for free exposure.

We promise never to send you spam and you can unsubscribe at any time!