Partnership expands reach of 3D printed spacer technology

Australian wastewater treatment solutions provider, Osmoflo has partnered with US-based Aqua Membranes, to provide enhanced system performance, as well as next-generation and optimised desalination solutions.

Expanding to new markets

The collaboration will combine Aqua Membranes' 3D Printed Spacer Technology for Reverse Osmosis (RO) membranes with Osmoflo's integration and operational expertise in delivering innovative, water and wastewater treatment solutions to both the municipal and industrial sectors.

Under the terms of the agreement, Osmoflo will distribute Aqua Membranes' RO membrane incorporating its patented 3D-printed spacer technology to clients, asset owners and original equipment manufacturers (OEM) across Australia, New Zealand and the Pacific region. Osmoflo will also use the printed membranes in its own integrated water treatment systems and processes.

The agreement will also see Osmoflo investing in Aqua Membranes as part of its Series B fundraising activities with the support of Kanadevia Corporation (an Osmoflo shareholder based in Japan). This investment will be used to expand Aqua Membranes' manufacturing capacity in the US, as well as its global supply capabilities.

Aqua Membranes CEO, Craig Beckman was delighted with the agreement: “We are thrilled to announce this investment and distribution agreement between Osmoflo and Aqua Membranes. Osmoflo is an exceptional company that shares our commitment to developing innovative solutions to address the ever-evolving water crisis. We look forward to collaborating with them to demonstrate the effectiveness of our Printed Spacer Technology.”

Osmoflo CEO, Carmine Ciccocioppo, told media: “We are excited by the opportunities that this exclusive partnership with Aqua Membranes and the use of their groundbreaking membrane product present for Osmoflo – indeed, we have already observed its impressive performance compared to conventional spiral wound membranes in several of our plants over the last 12-18 months.”

He added: “This partnership further enables us to deliver on our core mission of providing innovative, sustainable and value-based water solutions that contribute to a circular economy.”

3-D Printed Spacer Technology

Aqua Membranes' patented 3D Printed Spacer Technology offers numerous advantages over traditional mesh spacers that have been largely unchanged for over 40 years, including improved energy efficiency, reduced fouling, and increased water production.

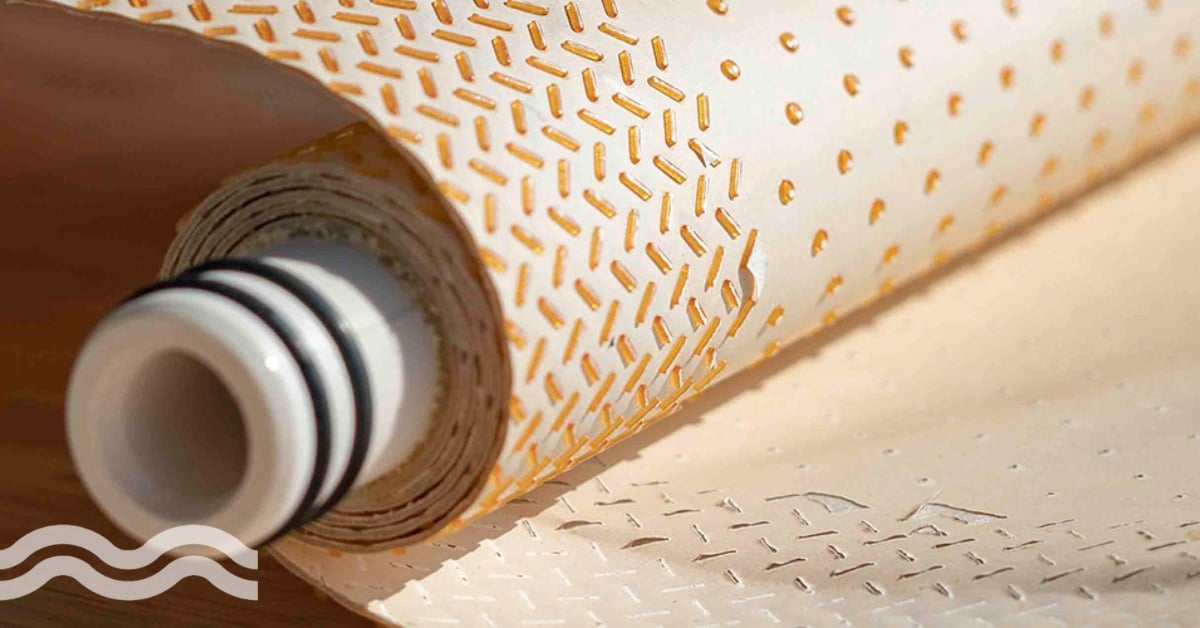

Aqua Membranes' Printed Space Technology removes the need for a mesh spacer. Instead of a separate element, a series of small features are 3D printed directly on to the membrane itself.

The features are engineered to fit their purpose, with the height of each feature determining flow profiles and channel dimensions that have demonstrated a 50-80 per cent reduction in pressure drop. The height of the features is far less than the old mesh spacers which allows for more membranes to be used in one module, allowing more water to be treated at lower pressures, with great recovery rates.

At the same time, fouling and clogging issues are reduced to optimise performance and lead to high recovery rates.

A significant advance that can help clients meet their goals

These benefits will also assist and allow clients to meet their obligations to decarbonise infrastructure and achieve their sustainability goals. At the same time, the technology can help to secure fresh water supplies, for example, through desalination, and meet the growing global demand for 'climate independent sources'.

Neil Palmer, Osmoflo's chief technology officer (CTO) said of the partnership: “Aqua Membranes' new approach to feed spacer technology is one of the most significant advances of RO technology since the development of thin film composite some 50 years ago. We have tested the new membranes over a long period on challenging industrial water and the results have exceeded our expectations.”

By reducing energy consumption and extending membrane lifespan, Aqua Membranes' technology can contribute to significant cost savings while minimising environmental impact.

The 3D printed membranes have the potential to process water sources that more conventional RO membranes are unable to treat.

Share your water technology stories with us

Do you have an innovation, research results or an other interesting topic you would like to share with the international water technology industry? The Aquatech website and social media channels are a great platform to showcase your stories!

Please contact our Sr Brand Marketing Manager Annelie Koomen.

Are you an Aquatech exhibitor?

Make sure you add your latest press releases to your Company Profile in the Exhibitor Portal for free exposure.

We promise never to send you spam and you can unsubscribe at any time!