NEOM: pioneering green hydrogen and internet of water (IoW)

Saudi Arabia's ambitious Neom City plans have been fleshed out with details on the vision for the global innovation hub. Key to the development is zero-liquid discharge water technologies and 100 per cent renewables that will be used to produce bulk hydrogen at low cost, as well as numerous other products derived from wastewater and water treatment.

Low cost renewables at the heart of water recovery

Blessed with prodigious solar energy potential as well as an attractive and complementary wind regime, Saudi Arabia plans to exploit its renewable energy resources and expertise in desalination to become a significant producer and exporter of green hydrogen, chemicals and fuels.

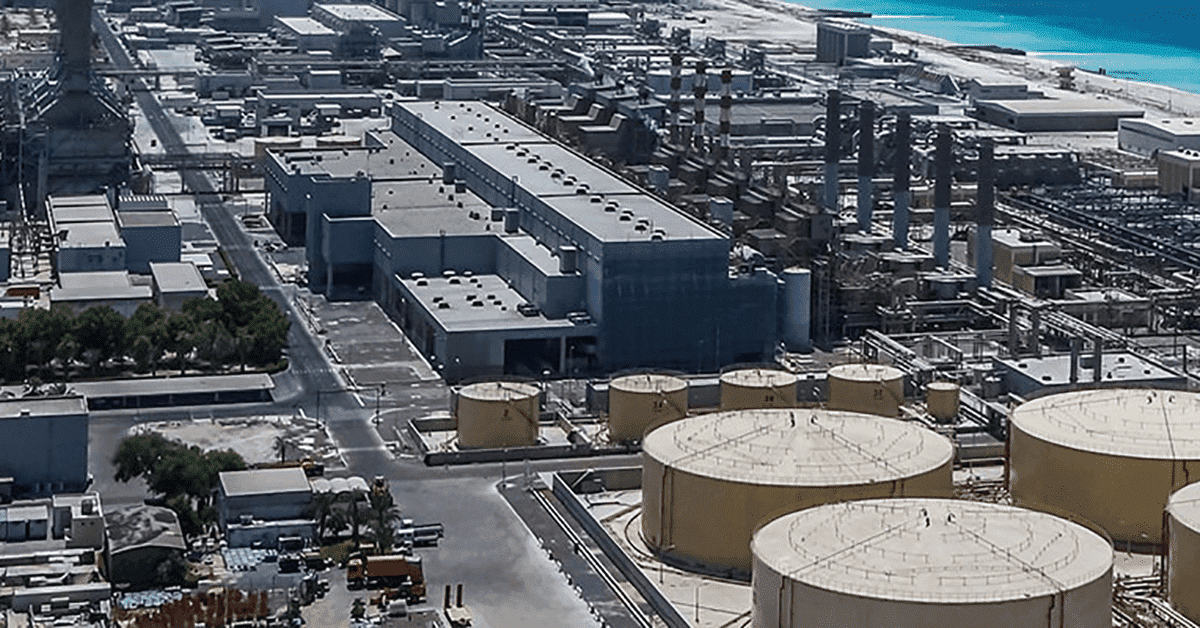

Located in Northwest Saudi Arabia with more than 450km of Red Sea coastline, NEOM will have access to a vast supply of seawater and intends to use this resource and its substantial renewable energy resources to produce desalinated water at “extremely low cost”.

NEOM’s water will be 100 per cent desalinated using renewable energy to ensure zero CO2 emissions as well as zero brine effluent discharges. Furthermore, any wastewater produced in the city will also be fully processed to generate energy, fertiliser and reusable fresh water for irrigation.

This goal is to achieve zero waste and a full circular economy for water and wastewater and to act as a global technology reference.

For example, NEOM plans to fully integrate advanced IoW (Internet of Water) infrastructure throughout its water distribution network. This will ensure minimal water loss while also supporting the development of interoperable, modular systems.

Speaking at GWI’s ‘Water and hydrogen for a sustainable future at Neom’ online event, Gavin van Tonder, water sector head at NEOM explained that the project aims to be a global powerhouse in water and energy production tech.

“NEOM aims to become a centre of excellence for global water technology, fully integrated along the value chain and anchored on water desalination.”

Working through dedicated partnerships and alliances, NEOM aims to become an accelerator of the second wave of energy transition and decarbonisation technology as part of a plan to wean Saudi Arabia itself off fossil fuels.

In addition, NEOM aims to become a centre of excellence for global water technology, fully integrated along the value chain and anchored on water desalination.

One of the goals of NEOM’s approach is to attract water-related research companies and start-ups, drive innovation and champion all elements of the water industry.

Integrating low-carbon technology for water

The principal aim of the NEOM project is to ensure that the production of hydrogen and water is maintained at the lowest cost possible while using natural competitive advantages, production and logistics assets to build on a growing global market. There are also substantial domestic off-take opportunities.

Supported by high capacity factors, NEOM will run on renewable energy at the lowest cost to become an integrated hub for the so-called second wave of energy transition and water production.

“From a water production perspective, we will be practising our recovery desalination fully with renewable energy, so this minimises the energy consumption,” noted van Tonder.

“We will also be doing high recovery reverse osmosis, so this enables us to get a lot more water out of it and also it enables us to have much less brine.”

Indeed, executing full seawater processing in parallel with hydrogen production, integrated hydrogen and chemical processing is at the heart of the NEOM energy and water nexus. This includes high recovery desalination, which minimises energy consumption and is based on zero liquid discharge (ZLD) water technologies.

On ZLD processes, a feasibility study has been taking place for the last three months.

“We are working with a variety of companies and a variety of technologies that can produce different minerals and chemicals,” says von Tonder.

For example, NEOM has conducted some analysis which reveals viable quantities of lithium in the water that may be extracted for commercial use.

“Executing full seawater processing in parallel with hydrogen production, integrated hydrogen and chemical processing is at the heart of the NEOM energy and water nexus.”

“The benefit that NEOM has is that we are all one company and we can talk to each other. We are not separate entities that want to work in separate silos. We will create local manufacturing and an export industry from seawater processing and hydrogen production,” van Tonder says.

He adds: "With green hydrogen, we have a lot of industrial processes that we will be able to perform, ammonia, fertiliser, steel refining and of course brine processing. The integration of brine processing and hydrogen is key. This is a bold move to activate the market for green hydrogen.”

Building low-carbon integrated production

Green hydrogen is a key driver for decarbonisation and will be driven by the city and its low-cost renewable energy.

In February, NEOM announced that it would use Concentrated Solar Heat to desalinate seawater. UK-based Solar Water Plc was appointed to build the first 'carbon-neutral' desalination plant featuring concentrated solar power that will heat a glass dome to boil seawater.

This was followed in July by the news that Air Products, in conjunction with ACWA Power and NEOM had signed a US$5 billion green hydrogen-based ammonia production facility which will be owned by the three equal partners.

This project alone is expected to save over three million tonnes per year of CO2 emissions.

The first partnership for NEOM, it will feature an integrated project with over 4 GW of solar, wind and energy storage.

As part of this deal, plans include the production of 650 tonnes per day of hydrogen by electrolysis with 2000 MW of power, production of nitrogen by air separation using Air Products technology as well as 1.2 million tonnes per year of green ammonia.

Scheduled to be onstream in 2025, Air Products will be the exclusive off-taker of the ammonia. The company intends to use it as a transport medium for bulk hydrogen for use in transportation with worldwide exports.

Related content

Share your water technology stories with us

Do you have an innovation, research results or an other interesting topic you would like to share with the international water technology industry? The Aquatech website and social media channels are a great platform to showcase your stories!

Please contact our Sr Brand Marketing Manager Annelie Koomen.

Are you an Aquatech exhibitor?

Make sure you add your latest press releases to your Company Profile in the Exhibitor Portal for free exposure.

We promise never to send you spam and you can unsubscribe at any time!