Series B funding will help meet demand for membrane tech

Aqua Membranes has secured an additional round of funding as it seeks to expand development and production of its reverse osmosis membrane elements with Printed Spacer Technology®.

Level of funding unspecified as interest in tech grows

The combined investment was led by Burnt Island Ventures and supported by Helios Climate Ventures, MUUS Climate Partners, and SQN Venture Partners. It includes equity and debt and will help meet increasing demand for the company's products.

The funding is expected to help:

- Increase capacity through automated production and additional equipment

- Establish a new state-of-the-art manufacturing facility in Knoxville, Tennessee, USA

- Expand the team by hiring additional staff, domestic and international

- New product development for sustainable membrane and separation technologies.

Craig Beckman, CEO of Aqua Membranes, told media: "We are deeply grateful to our new and existing investors – for their trust and belief in the important work we do every day for the future of clean water. This is an exciting time for our team. Fuelled by significant revenue growth in 2024 and this new capital investment, we are more committed and able than ever to drive reverse osmosis innovation and make clean water accessible for all."

Did RO membranes need a rethink?

For decades the method of 'deploying' separation membranes has been reverse osmosis (OS). But as lead investor, Tom Ferguson, managing partner at Burnt Island Ventures points out on his blog: "RO membrane elements haven't seen a step change improvement since the invention of the multi-leaf element by Don Bray in 1965, which is the design used in essentially all spiral elements today, and the invention of the thin film composite polyamide RO membrane by John Cadotte in 1979, which is the technology used by every major producer of RO membranes."

While improvements have been made over the years to bring small gains, the technology being used to construct membranes have remained largely the same since the late 60s. These membranes experience clogging problems and fouling, which requires off-line and often chemical cleaning. Traditional RO membranes also suffer from pressure drops that consume energy and drive up operational costs.

One component Ferguson considered in need of an entire rethink in spiral wound membranes was the mesh spacer, which he suggested offers poor fluid dynamics and suboptimal pressure drops. The mesh spacer provides uniform flow channels to help break up scaling and fouling.

Ferguson continued: "The mesh spacer looks like a window screen made of plastic, with two intersecting strands - it's not highly engineered, not purpose designed, but cheap, available, and proven. While it's obvious that the mesh spacer is non-ideal, its use still persists."

Controlling the flow without the mesh

Aqua Membranes' Printer Space Technology (PST) removes the need for a mesh spacer. Instead of a separate element, the PST prints a series of small features directly on to the membrane itself.

The features are engineered to fit their purpose, with the height of each feature determining flow profiles and channel dimensions that have demonstrated a 50-80 per cent reduction in pressure drop. The height of the features is far less than the old mesh spacers which allows for more membranes to be used in one module, allowing more water to be treated at lower pressures, with great recovery rates.

At the same time, fouling and clogging issues are reduced to optimise performance and lead to high recovery rates.

On his decision to invest, Ferguson wrote on his blog: "The Aqua Membranes innovation is a clever, well-patented innovation that is quickly gaining market adoption and is winning industry awards. We frankly don't see why their tech won't become an industry standard."

The PST can be applied to the standard flat-sheet membranes, they are also designed to industry specifications which means there is a low-barrier to adoption.

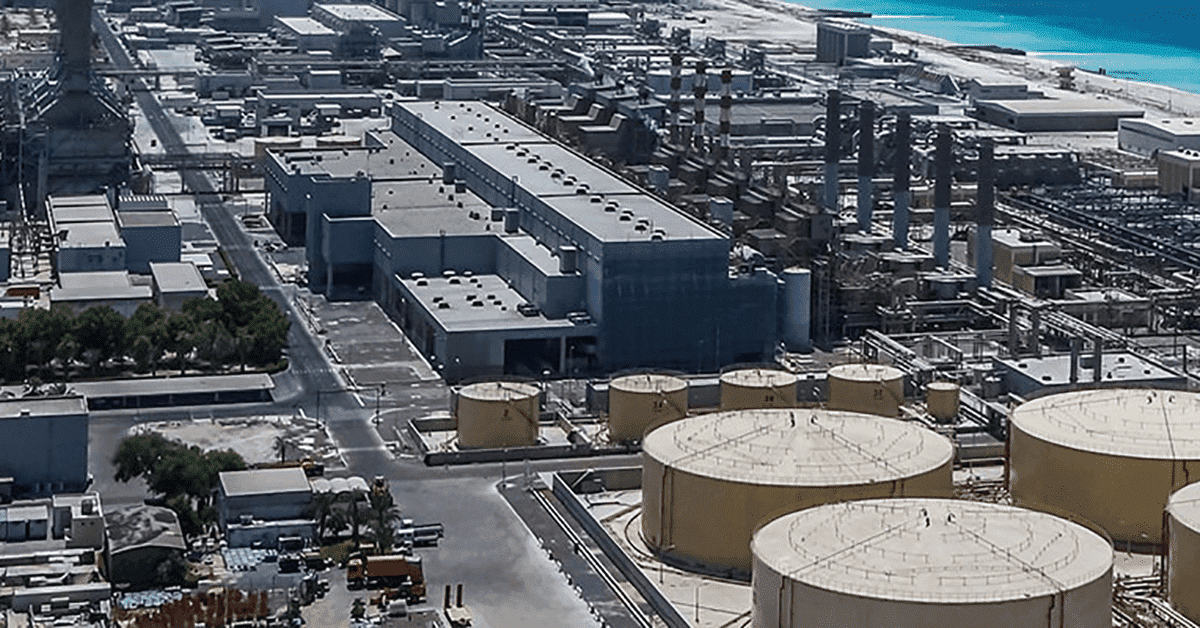

Turning focus to desalination

Earlier in the year, Aqua Membranes was recognized by Global Water Intelligence (GWI) as the Breakthrough Technology Company of the Year in the 2024 Global Water Awards. With innovation as a driver, the company has moved into related areas of water treatment.

The company recently completed the first round of 8040 element testing of a new patented seawater membrane pattern, using Printer Spacer Technology. Tests revealed significant improvements in performance when subjected to industry-standard SW test conditions: An average 99.8 per cent salt rejection, while increasing output by an average of 41 per cent relative to the same flat sheet in a conventional element.

This patented design, specifically engineered to meet the rigorous demands of desalination, offers significant improvements in element performance. In our recent tests, the new pattern achieved an average 99.8% salt rejection in industry-standard SW test conditions while increasing output by an average of 41% relative to the same flat sheet in a conventional element, a result that has the potential to revolutionize the seawater desalination market, making it more efficient and sustainable.

Craig Beckman, CEO at Aqua Membranes told media: "This breakthrough brings us one step closer to making desalination a more accessible and environmentally friendly option to address the global water crisis."

The elements will now be further validated in a pilot project.

We promise never to send you spam and you can unsubscribe at any time!