Desalination: our essential guide to desalination and the global water crisis

Our essential guide to desalination and the global water crisis

Table of contents

Desalination: Quenching growing thirst around the world

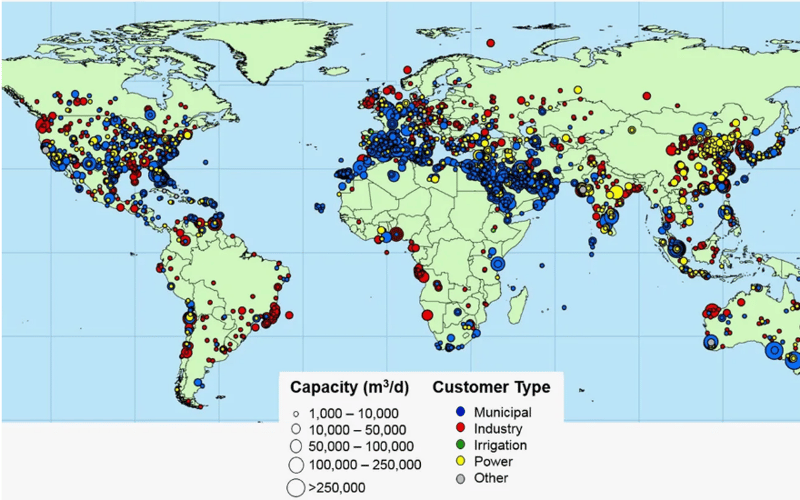

With more than 22,000 plants now contracted around the world, desalination is enabling countries to provide water security for future generations amid growing climate concerns. By converting saline water, the process can offer freshwater in areas lacking natural groundwater, or surface water supplies.

Together with water reuse, desalination can offer a robust solution to water scarcity and in some countries, provides over 90 per cent of total water supply. The rapidly growing advance in water reuse, particularly direct and indirect potable reuse of municipal wastewater, uses desalination membrane technology. There are now over 1350 water reuse plants globally.

What are the processes and technologies involved in desalination? What’s the difference between MED and MSF thermal treatment? What are the pros and cons of desalination? Our essential guide dives deeper into desalination and the processes involved.

What is desalination?

Desalination, the process of making water drinkable by removing salt, involves treating sea or brackish water using technologies in desalination plants, from pre-treatment to pumps and membranes.

The global installed desalination capacity is 97.4 million m3/day, with a cumulative contracted capacity of 104.7 million m3/day, according to the IDA Water Security Handbook.

As of June 2018, over 20,000 global desalination plant contracts exist, supplying just one percent of the world's drinking water but experiencing yearly growth. The advantage of desalination is the oceans, containing over 97.2 percent of the planet’s water resources, making it "drought-proof and practically limitless."

Desalination targets either brackish water (salt content < 10,000 mg/L) or seawater (salinity range: 30,000 to 44,000 mg/L).

Besides brackish and seawater, sources may include wells, surface water (rivers and streams), wastewater, and industrial feed/process waters, according to the (American Membrane Technology Association).

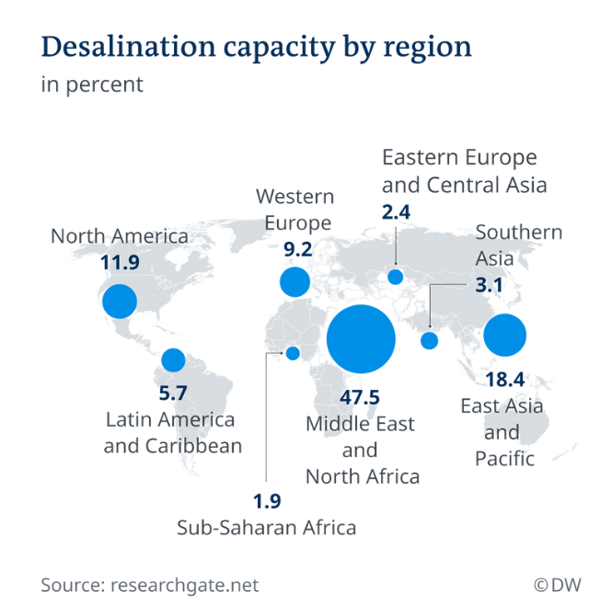

Around 44% of the global desalination capacity is in the Middle East and North America, with an anticipated annual growth rate of 7-9%. Accelerated desalination activity is expected in “hot spots” such as Asia, the US, and Latin America, according to the IWA.

The IDA reported a 21% growth in the industrial desalination market between 2016-2017, mainly driven by significant contributions from oil & gas activities in. In the first half of 2018, mining contracted over 200,000 m3/day of new capacity, while the microelectronics industry doubled its contracted capacity between 2016-2017, creating new opportunities for desalination technologies.

What are the desalination processes?

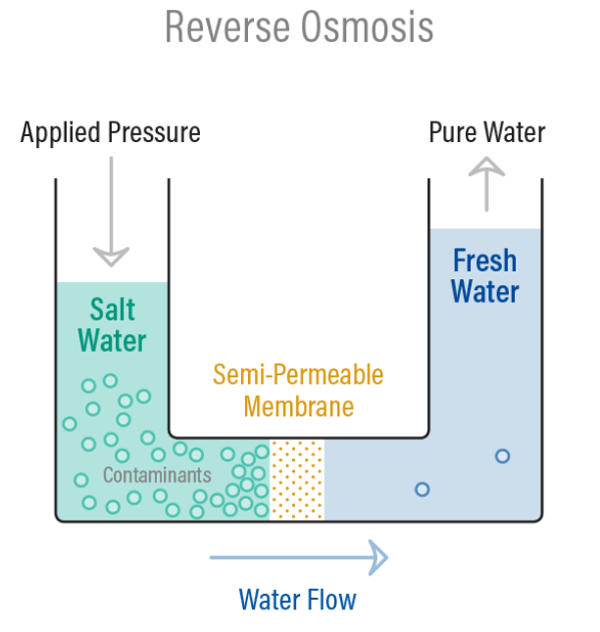

There are two main types of desalination processes: membrane (reverse osmosis (RO) and nanofiltration (NF) and thermal, which includes multi-effect distillation (MED), multi-stage flash distillation (MSF) and mechanical vapour compression (MVC). Other technologies and processes include electrodialysis (ED), forward osmosis (FO) and membrane distillation (MD).

Membrane-based desalination continues to provide the vast majority of installed desalination capacity. To put this into perspective, in 2017, membrane technology accounted for 95.6 per cent of annual contracted capacity while thermal processes account for a mere 4.4 per cent.

Membrane desalination

AMTA reports that Reverse osmosis (RO) and Nanofiltration (NF) are the leading pressure-driven membrane processes. In terms of membrane configurations, the options include spiral wound, hollow fibre, and sheet, with spiral being the most widely used.

Contemporary membranes include primarily polymeric materials with cellulose acetate still used to a much lesser degree. One notable example is the thin-film composite (TFC) membrane, which includes polyamide as an active layer.

Depending on feed water salinity, operating pressures for RO and NF are in the range of 50 to 1,000 PSIG (3.4 to 68 bar, 345 to 6896 kPa). The seawater RO requires electric power of 3.0 to 3.5 kWhr/m3.

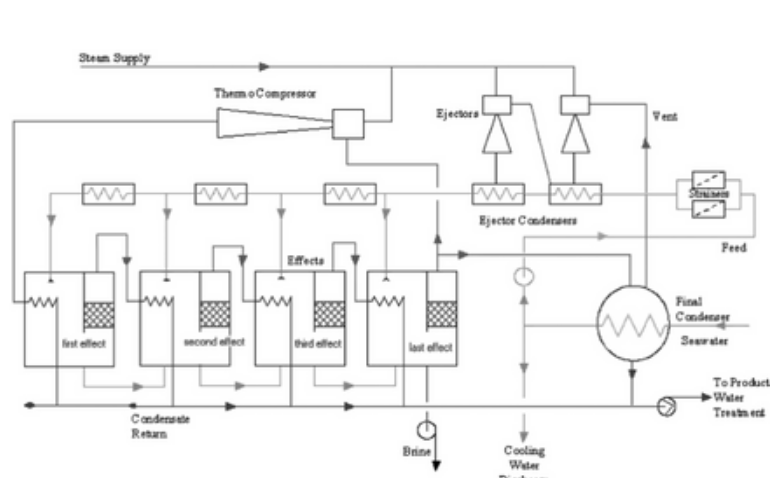

Multi-effect distillation (MED)

A low-temperature thermal process, MED obtains freshwater by recovering the vapour of boiling seawater in a sequence of vessels, known as the multiple ‘effects’.

Vapour boiled off in one vessel can then be used to heat the next one, as the boiling point of water decreases at the same time as the pressure decreases.

To summarize, in the MED process, from the initial to the final vessel, both pressure and temperature decrease progressively from hot to cold.

For the MED process, a heat input and electric power ranging from 0.9 to 1.5 kWhr/m3 are required.

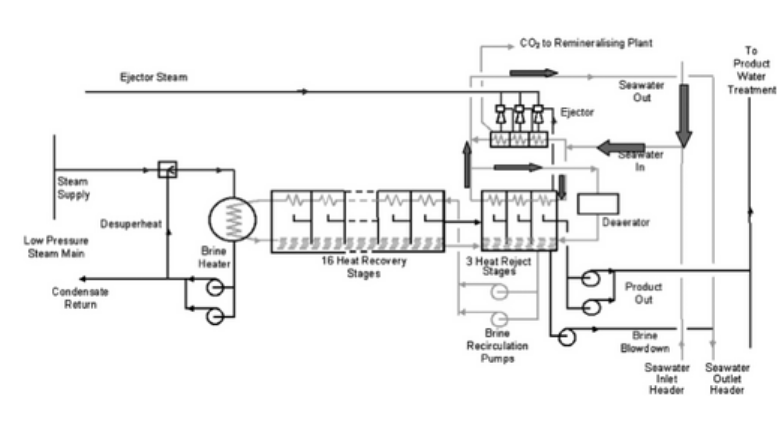

Multi-stage flash distillation (MSF)

Commercially used since the 1950s, multi-stage flash (MSF) desalination involves multiple stages.

Seawater or recycled brine is heated by steam in the Brine Heater. The heated seawater then flows through evaporator stages, causing flashing to generate water vapor. The vapor condenses on tubes, collecting as distillate.

Heat recovery stages play a crucial role in the MSF process. They pre-heat seawater brine and recover heat. In the last stages, brine blowdown and distillate are cooled, and excess heat is rejected.

Overall, the MSF process requires 3.5 to 4.5 kWhr/m3 of heat input and electric power.

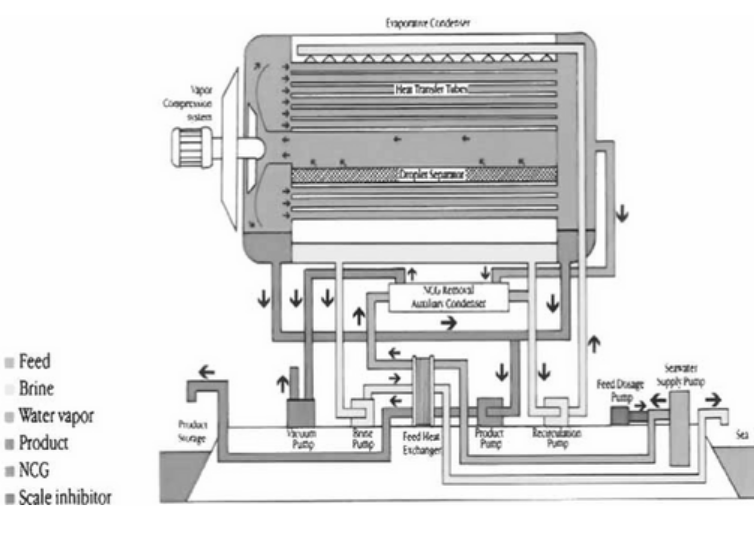

Mechanical vapour compression (MVC)

In the MVC process, seawater enters the pre-heater unit, exchanging thermal energy with concentrate and product water effluents. The pre-heated seawater is sprayed over bundles of heat exchange tubing, which are at a higher temperature than seawater, leading to partial evaporation.

Water vapours produced undergo compression using a mechanical compressor, and the compressed vapour is pumped inside the tubing of heat exchange bundles. Within the tubing, the compressed vapour condenses, releasing energy that is transferred to seawater sprayed over the tubing, causing it to evaporate.

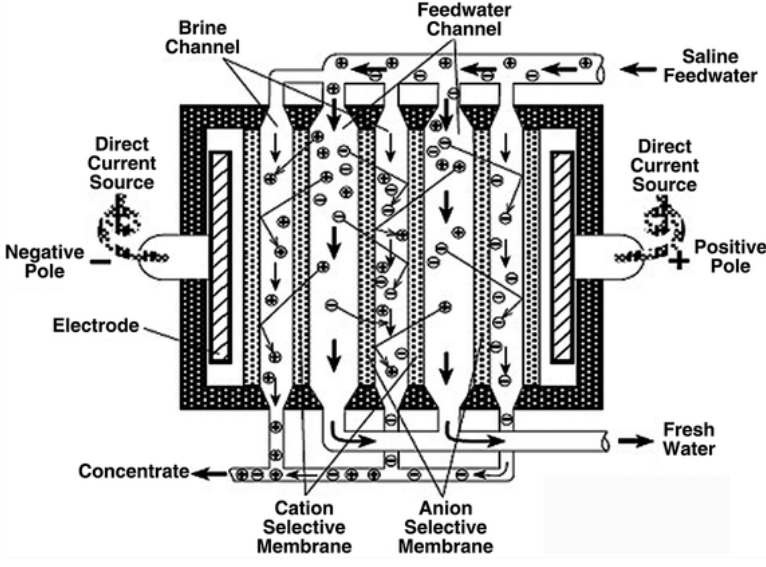

Electrodialysis (ED)

Electrodialysis (ED) and Electrodialysis Reversal (EDR) processes rely on direct current (DC). In these processes, ions flow through ion-selective membranes towards electrodes with opposite charges, as specified by AMTA. This stands in contrast to the movement of water in pressure-driven processes mentioned earlier.

In EDR systems, there is a periodic reversal of the polarity of electrodes. Ion-transfer (perm-selective) anion and cation membranes effectively separate the ions present in the feed water.

These systems find primary application in waters characterized by low total dissolved solids (TDS).

Forward Osmosis (FO)

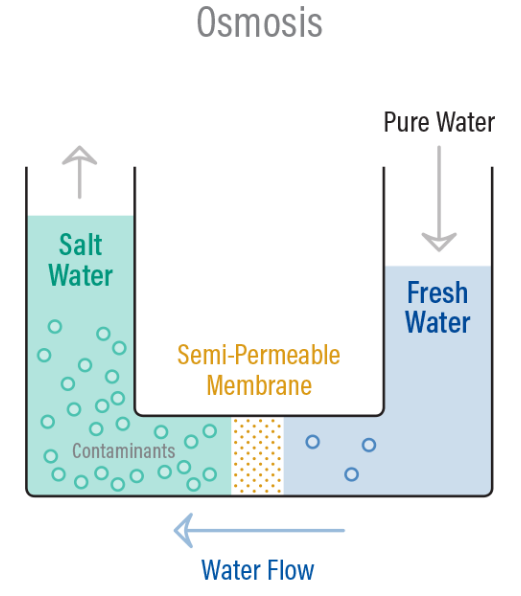

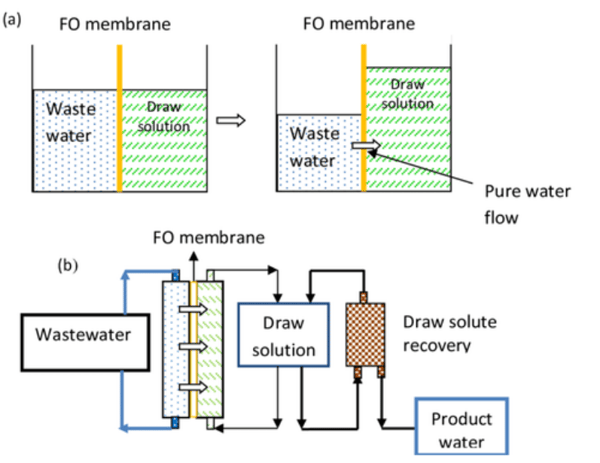

Compared to reverse osmosis (RO), where saline water is pushed through a membrane, forward osmosis (FO) takes a different approach. FO utilizes osmotic pressure generated from a natural salt concentration gradient as the driving force through a membrane. In this process, the feedwater, often seawater, is on one side, followed by a membrane, and then a draw solution on the other side.

According to AMTA, without applying any external pressure, the water from the feed solution naturally migrates through the membrane to the draw solution. This results in a diluted solution. Subsequently, the diluted solution is processed to separate the product from the reusable draw solution.

Desalination costs

Desalination costs consists of various factors: fixed costs (37%), labour (4%), maintenance and parts (7%), membrane replacement (5%), consumables (3%), and electrical energy (44%).

Historically perceived as costlier than traditional surface or groundwater treatment at approximately US$1 per cubic meter ($/m3), desalination has seen a recent breakthrough. Advances in technology and equipment over the last 20 years have contributed to an 80% reduction in overall costs, encompassing both operational (OPEX) and initial capital expenditure (CAPEX).

Desalination prices in recent tenders in Abu Dhabi, Saudi Arabia, and Israel have dipped below $0.50/m3 for the first time. Christopher Gasson, GWI's publisher, foresees 2019 as the best year in the desalination market, countering a decade of rising prices due to high materials and energy costs.

Seawater desalination costs at $0.40/m3 are nearing the $0.30-$0.40 range of indirect potable reuse, according to the IDA Water Security Handbook, citing various factors for the historically low costs.

This entails “cost-efficient optimization of the construction process” based on contractors' experience with large-scale projects. Alongside new contractual and financial models and reduced interest rates, these measures aim to “push tariff downs.”

Furthermore, the declining cost of desalination plant components, influenced by lower petroleum prices, is additionally aiding in price reduction.

“Additionally, energy savings has been realized through advances in membranes that require less inlet pressure, energy-efficient recovery devices, and larger reverse osmosis trains with larger pumps and motors capable of higher efficiencies,” added Carlos Cosín, IDA and CEO of Almar Water Solutions.

What are the world's largest desalination plants?

As reported by Aquatech Global Events, the Rabigh 3 project recently awarded in Saudi Arabia was considered one of the world’s largest plants, with a capacity of 600,000 m3/day. However, there are much larger desalination plants in operation around the world. Below is a list of five of the world’s largest projects.

1 | Ras Al Khair, Saudi Arabia: 1,036,000 m3/day

Commonly regarded as the desalination heavyweight of the world, the massive Ras Al-Khair is a hybrid project that uses both thermal multistage flash (MSF) and reverse osmosis (RO) technologies. Located 75km north-west of Jubail and serving Riyadh, the site also has a substantial power generation component, with a capacity of 2,400MW. The main contractor for plant construction was Doosan and its consortium partner Saudi Archirodon, with Poyry acting as the consultant for the project.

2 | Taweelah, UAE – 909,200 m3/day

The Emirates Water and Electricity Company and ACWA Power have signed a water purchase agreement for the world’s largest seawater reverse osmosis desalination plant. The plant, located at Taweelah Power and Water Complex, 50 km north of Abu Dhabi, has a cost of US$847m and a desalinated water tariff of 49.05 cents/m3.

ACWA Power, the lead developer with a 40% share, confirmed successful financial closing. Construction began in May 2019, and the project is set for completion in October 2022, aiming to deliver 909,200 cubic meters of water daily. The Taweelah development is expected to increase Abu Dhabi's RO-produced water from 13% to 30% by 2022.

3 | Shuaiba 3, Saudi Arabia – 880,000 m3/day

ACWA Power chose Siemens and Doosan to form a consortium for the construction of a power plant and thermal desalination plant. An expansion of the plant has already been completed.

Another expansion is currently in the final construction stage, and according to ACWA Power, it will add a total of 400,000 m3/day of reverse osmosis (RO) capacity.

Upon completion of these expansions, the Shuaiba plant is poised to surpass Ras Al Khair as the largest operating desalination facility. It is expected to achieve a remarkable total capacity of 1,282,000 m3/day.

4 | Sorek, Israel – 624,000 m3/day

Sorek, boasting a substantial capacity of 624,000 m3/day, is a prominent global membrane plant. Situated 15km south of Tel Aviv in Israel and developed by IDE Technologies, its distinctiveness lies in the use of 16-inch seawater reverse osmosis membranes arranged in a unique vertical formation.

IDE Technologies, in partnership with Bank Leumi, successfully secured the PPP tender for Sorek 2, marking their fourth triumph out of five tenders for desalination plants in Israel. The unprecedented bid of USD 0.41 per cubic meter is geared towards an annual production of 200 million cubic meters of water, with a nominal capacity of 548,000 m3/day.

Upon completion, Sorek 2 is poised to join the distinguished ranks of Israel's desalination plants, alongside Hadera, Ashkelon, the first Sorek, Palmachim, and Ashdod.

5 | JUBAIL 3A IWP - 600,000 m3/day

In April 2020, a consortium led by ACWA Power, including Gulf Investment Corporation (GIC) and Al Bawani Water & Power Company (AWP), signed a significant 25-year water purchase agreement with the Saudi Water Partnership Company (SWPC).

Under the terms of this partnership, the ACWA Power-led consortium is tasked with various responsibilities, including designing, constructing, commissioning, operating, and maintaining the Jubail 3A Independent Water Plant (IWP) in Saudi Arabia. This encompasses not only the desalination plant but also associated potable water storage and electrical special facilities.

The ACWA consortium has achieved a significant milestone by securing the lowest levelized water cost at USD 0.41 per m3. This accomplishment is particularly noteworthy in the context of the overall project, which involves a substantial investment of USD $650 million.

The Jubail 3A IWP is anticipated to contribute significantly to the production of potable water, targeting an impressive 600,000 m3 per day. This greenfield seawater reverse osmosis desalination project is strategically located in Jubail, Kingdom of Saudi Arabia.

A consortium comprising Power China, SEPCO-III, and Abengoa has secured the Engineering Procurement Construction contract.

Pros and cons of desalination

Cons of desalination

One of the wider environmental challenges associated with desalination is managing the by-product of brine – a high salinity waste produced during the process.

In 2019, the United Nations (UN) endorsed a paper titled 'The State of Desalination and Brine Production: A Global Outlook,' acknowledging brine as a 'salty dilemma.' Globally, desalination plants collectively discharge 142 million cubic meters of hypersaline brine daily.

Four Middle Eastern nations – Saudi Arabia, Kuwait, UAE, and Qatar – contribute more than half of the global brine output. The report highlights that Middle Eastern plants produce “four times as much brine per cubic meter of clean water” compared to plants using river water membrane processes. It's crucial to note that river water has lower salt levels than seawater, introducing an uneven basis for comparison.

Another concern in the operation of open ocean intakes for seawater desalination plants is the potential impact of impingement and entrainment (I&E).

Impingement involves organisms large enough to avoid passing through screens getting trapped against them due to the force of the flowing source water, as explained by the EPA.

Entrainment, on the other hand, occurs when marine organisms enter the desalination plant intake, move through the intake system, and pass through the treatment facilities.

The environmental impacts on marine organisms caused by impingement and entrainment of seawater intakes are site-specific, notes the Water Reuse Association. These impacts can vary significantly from one project to another, and modern plants adhering to environmental standards typically experience extremely low levels of I&E.

Pros of desalination

Desalinated water is relied upon by over 300 million people worldwide for their daily needs. This practice spans 150 countries, with a total of 22,757 contracted desalination plants globally.

In the future, the increasing global demand for fresh water, coupled with uneven distribution and limited availability of freshwater supplies, poses a challenge. Climate change further exacerbates this issue by intensifying droughts and floods. Desalination emerges as a crucial solution, providing a reliable source of potable water from seawater to meet the growing water demand.

Desalination, along with water reuse, offers countries a dependable strategy to supplement their existing water resources and acts as an 'insurance policy' against potential shortages. According to the IDA, these non-conventional and environmentally sound solutions align with a circular water economy, addressing water scarcity.

In parallel, advancements in coupling desalination processes with renewable energy, such as solar photovoltaic, are gaining momentum. The integration of renewable and desalination technologies aims to reduce the carbon footprint of desalination in the short term.

The ongoing evolution of battery technology is considered pivotal in achieving a 24/7 independently powered desalination plant. The Global Clean Water Desalination Alliance has set a goal for 20% of new plants, between 2020 and 2025, to be powered by renewables.

We promise never to send you spam and you can unsubscribe at any time!