How could carbon diversion unlock energy savings for WWTPs?

What is carbon diversion?

As the water sector seeks to become more energy-efficient, carbon diversion (also known as enhanced primary treatment) could prove a critical tool for utilities looking to squeeze maximum value out of their operations. Boasting the dual benefits of reducing aeration energy consumption and increasing biogas generation, a variety of methods of carbon diversion are gaining a growing foothold in the market.

Within wastewater treatment plants, the most energy-hungry stage is aeration, which employs blowers to introduce air to ensure the right conditions for aerobic biological treatment processes to take place. While this is a vital step to ensure that wastewater is treated effectively, it is also ripe for optimisation to achieve strong results while reducing energy consumption.

This is where carbon diversion can step in. It involves reducing the organic load on secondary treatment systems by redirecting more biochemical oxygen demand (BOD) towards the sludge line at the primary treatment stage. As a result, this reduces the aeration requirements of these downstream biological processes.

WWTPs employing anaerobic digestion are best-placed to capitalise on the additional benefit of increasing the volume of biogas generated by diverting more organics to sludge at an early point in the treatment train. Depending on the operating conditions and method of enhanced primary treatment, it could be possible for WWTPs to increase biogas generation by 20-65% while reducing aeration energy consumption by 10-30%.

Counting on chemicals

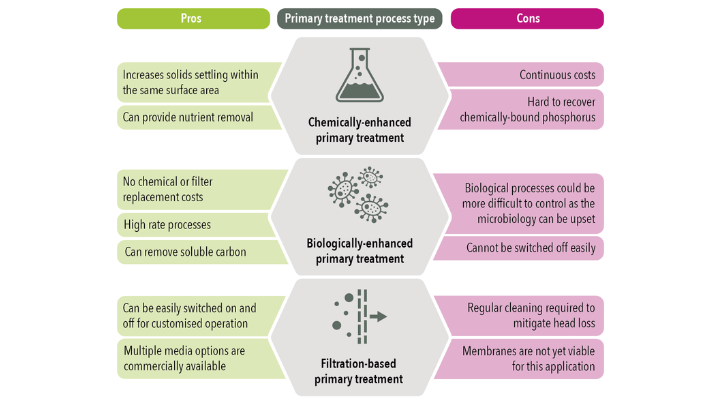

There are three types of carbon diversion: chemically-enhanced, biologically-enhanced and filtration-based. Adding chemicals to existing clarifiers can facilitate faster settling of suspended solids without extensive infrastructure modifications, by forming larger or heavier flocs which settle to the bottom of the tank.

However, using additional chemicals represents an extra operational cost for utilities, which must be weighed up against the benefits of spending less on energy for aeration. While chemically-enhanced primary treatment can also remove phosphorus, it is then difficult for chemically-bound phosphorus to be recovered, which is a growing consideration for utilities, particularly in Europe.

A variation of chemically-enhanced primary treatment is ballasted clarification, which uses a microsand or magnetic material to enhance the settling of particles that would typically be too small to settle in traditional gravity-driven tanks. While chemical coagulants and flocculants are widely available on the market, leading providers of ballasted clarification systems include Veolia Water Technologies, Evoqua and WesTech Engineering. The materials which enhance the settling process are also continuously reused within the system, cutting down on operational costs in comparison with purely chemical-based processes.

Technology pros/cons

Technology pros/cons

Source: GWI

Fitting in filtration

For utilities looking to explore chemical-free options for carbon diversion, a growing trend is the use of filters to enhance primary treatment by removing more suspended solids upstream of biological processes.

A range of different filter types and configurations are being applied for this purpose, with promising options including cloth disc filters and compressible media filters. For example, Aqua-Aerobic Systems’ AquaPrime product is a modified version of its tertiary disc filter, which features a specially engineered cloth media and increased basin depth to tailor it for use in enhanced primary treatment.

Another technology targeting this application is Tomorrow Water’s Proteus Primary filter, which uses a cross-shaped media to increase filtration surface area by 50%. It has already been installed at sizeable wastewater treatment plants in Korea, in addition to pilot projects in US states such as Milwaukee. Tomorrow Water also offers the option to add further chemical enhancements to the filter to tackle peak unpredictable flows, which is a growing challenge for utilities dealing with the effects of climate change on wet weather events.

Spelling out the biological options

An emerging opportunity in the primary treatment market is the implementation of biological treatment processes for carbon diversion. While physical and chemical processes can only remove suspended material, biological processes can also remove soluble matter, which comprises a large proportion of municipal wastewater.

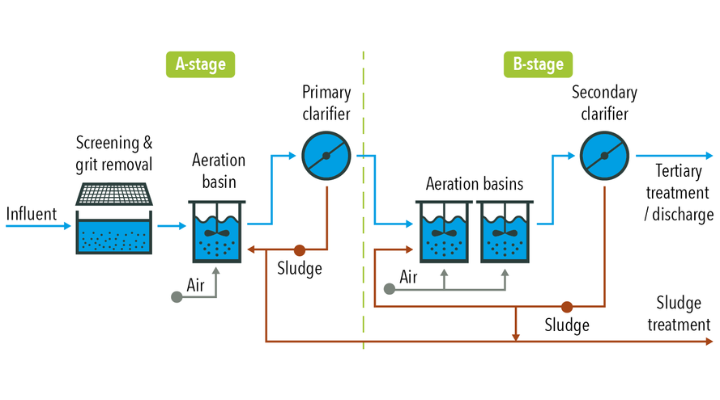

A few different configurations of biologically-enhanced primary treatment are available, with the most common being the A-stage process. This involves setting up a small high-rate activated sludge system in the primary reactor: the bacteria absorb soluble carbon from the wastewater but do not metabolise it, instead settling into the waste sludge alongside the excess carbon.

A further option is the A/B process, which represents a modification to the traditional activated sludge process and uses a combination of adsorption and bio-oxidation to divert carbon. A short retention time results in reduced aeration energy consumption, while soluble material is absorbed quickly but not broken down.

A/B process diagram

A/B process diagram

Source: Water & Wastes Digest

Innovations in this market are seeking to combine treatment processes in new ways, with one notable example being the alternating activated adsorption (AAA) clarifier, licensed by NEWhub Corp. The A-stage process is integrated with contact stabilisation and directs flow to the bacteria layer, where they bind carbon to their surface and undergo biosorption. The technology is well-suited to smaller treatment plants and is building from its existing reference base in Europe to explore markets in the US and Australia.

A balancing act

Reducing energy consumption is a main draw for implementing any kind of enhanced primary treatment, but it is not a simple decision for utilities to make, as carbon is also a critical component in enabling nutrient removal. Remove too much carbon at the primary stage, and biological processes will require an additional source of carbon to perform properly to meet discharge standards.

Nutrient removal regulations are therefore a key consideration, with standards tightening across the globe amid efforts to protect natural habitats and water bodies. In Europe, for example, the EU proposed updates to the Urban Waste Water Directive in October 2022 which intend to slash total nitrogen and phosphorus limits to 6mg/L and 0.5mg/L respectively. While utilities may be eager to optimise efficiency and implement savings, meeting regulatory limits will ultimately be the top priority.

However, as new methods of nutrient removal develop, the need for carbon in the secondary treatment tank may be reduced. One intriguing option is anaerobic ammonium oxidation: while widespread commercial adoption of mainstream anammox remains a distant prospect, in future it could offer the option of diverting even more carbon to sludge. For now, however, utilities must balance the competing priorities of energy reduction with the need to meet stringent nutrient removal requirements.

The most imminent markets for carbon diversion will be larger utilities across Europe, the US and East Asia, where efforts to boost the efficiency sustainability of wastewater treatment processes are gaining increasing traction. As a growing number of utilities implement carbon diversion practices, these processes demonstrate the synergies available for accelerating the development of energy-positive WWTPs within an efficient site footprint.

This article has been produced by our knowledge partner, GWI.

We promise never to send you spam and you can unsubscribe at any time!