Beyond Biogas: Three exciting Australian projects recovering energy and other useful by-products from wastewater or sewage sludge

Beyond Biogas: Three exciting Australian projects recovering energy and other useful by-products from wastewater or sewage sludge

Energy recovery from wastewater and sludge is becoming a firm favourite for utilities as it blends circularity with energy efficiency and decarbonisation. Biogas recovery may be established in the water industry, but there are other innovative pathways to recover energy from sewage sludge or wastewater, and some have the potential to generate other valuable by-products.

Here GWI explores three exciting energy recovery projects in Australia, in the form of biomethane and hydrogen production, and how the participants are also exploring the ability to make graphene and oxygen.

Circularity down-under

The global water and wastewater industry is increasingly viewing waste products as valuable resources rather than a burden, and Australia is one of the global leaders in terms of ground-breaking and innovative water-related circular economy projects.

Each of the following three projects have received government funding, including two from the Australia Renewable Energy Agency (ARENA). This federal government funding pot helps various projects in pursuit of the energy transition, including solar power and hydrogen generation, as well as energy recovery from sewage, agricultural and municipal waste streams.

State-based funding is also available, with the Queensland Government’s Hydrogen Industry Development Fund currently committing up to $2AU million to the Goondiwindi Hydrogen Project.

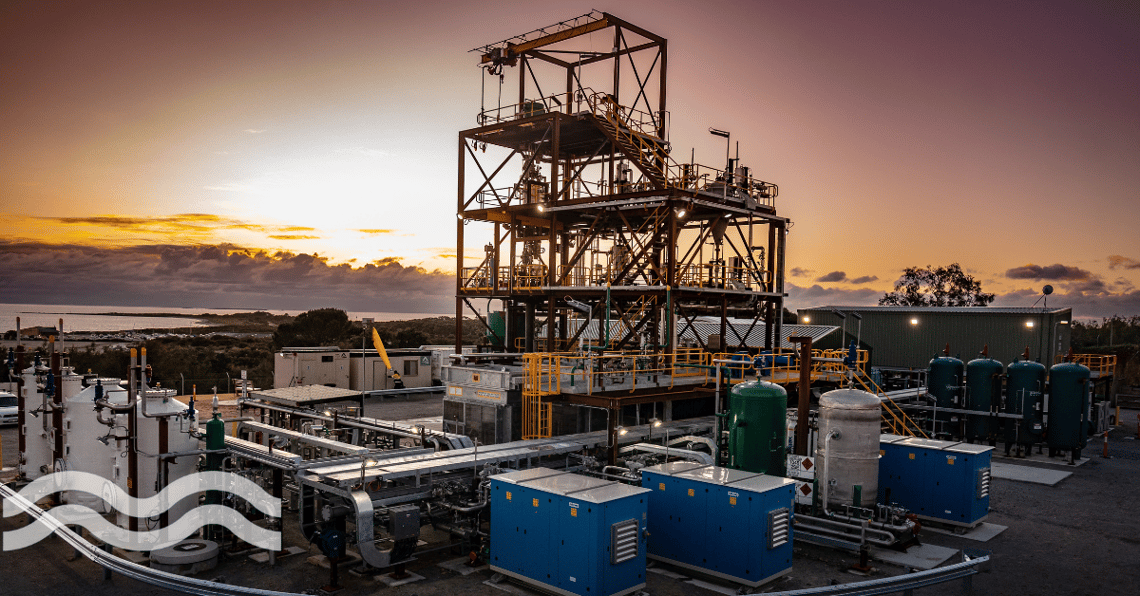

Perth, Western Australia: Using biogas to produce hydrogen and graphite

A world-first project is underway to turn biogas into hydrogen and synthetic graphite using the Hazer Process, a proprietary technology of the Hazer Group. The process is a type of methane pyrolysis, where an iron ore catalyst and a high temperature are used to split the methane contained in biogas into hydrogen and graphite.

The facility, referred to as the Commercial Demonstration Plant (CDP), is located at the Woodman Point Water Resource Recovery Facility, owned by the Western Australia Water Corporation. The CDP is set to begin production in late 2023 and will produce approximately 100 tonnes per annum of hydrogen and 380 tonnes per annum of graphite.

Hazer claims its process is more energy-efficient and cost-effective than water electrolysis, which requires significant amounts of electricity, and has better emissions credentials than steam methane reforming. Compared to steam methane reforming, which has a significant carbon footprint, the Hazer Process boasts impressive decarbonisation credentials. The carbon contained in the methane feedstock is captured in graphite. When biogas, a renewable form of methane, is used as the feedstock it results in a “carbon negative situation” according to Hazer.

The graphite by-product brings a unique value proposition as it could be sold for revenue (for example for steel, concrete or carbon black applications), thereby reducing the cost of hydrogen generation. A memorandum of understanding has already been signed with Mitsui, a leading Japanese trading and investment group, to investigate the global markets for Hazer graphite.

A global expansion of the process is underway with upcoming facilities in Canada, Japan and France already in the pipeline with expected start-up dates ranging between 2025 and 2028. Each of these plants will be a significant scale-up from the CDP with initial outputs 25 times larger, at 2,500 tonnes of hydrogen a year. In France, Hazer is working with major French energy utility ENGIE to build a plant, with a pre-feasibility study already demonstrating that the produced hydrogen will meet EU standards.

Source: Hazer Group Limited

Sydney, New South Wales: Injecting biomethane into the gas grid

In June 2023, a collaborative project between Sydney Water and Jemena, the largest gas distributor in New South Wales, facilitated the first injection of biomethane from municipal wastewater into Australia's natural gas grid. Biomethane, in this context referred to as 'renewable natural gas', has significant potential to replace some fossil fuel natural gas within the network due to its chemical similarity to fossil methane and full compatibility with existing gas appliances.

Initially, the project (referred to as the Malabar Biomethane Demonstration Project) will produce approximately 95 terajoules of renewable natural gas annually, equivalent to the average yearly consumption of around 6,300 homes – with the potential to more than double its output to 200 terajoules annually. The project also boasts strong sustainability credentials, as it is expected to initially prevent 5,000 tonnes of carbon dioxide emissions per year, with the potential to scale this up to 11,000 tonnes.

The feedstock for the biomethane is biogas produced through the anaerobic digestion of sewage sludge at Sydney Water’s Malabar Water Resource Recovery Facility (WRRF). At the new Malabar Biomethane Injection Plant (MBIP) the biogas is purified into biomethane via a biogas upgrading process and injected into the network. The funding for the project was split between Jemena and ARENA, at an estimated cost of $16AU million.

The biomethane output has a guaranteed end-market, with Origin Energy (one of Australia’s leading energy retailers) signing an offtake agreement with Jemena in March 2023, committing to purchase all the biomethane produced at the plant during its initial 18 months of operation. Additional offtake markets may surface if the project becomes certified in a pilot certification process by Greenpower, a renewable energy accreditor recognised by the NSW government. If certified, the Malabar site could generate renewable gas certificates for sale to commercial and industrial gas customers.

[Source: Shutterstock; arturnichiporenko]

Goondiwindi, Queensland: Using recycled wastewater to produce hydrogen and electrolytic oxygen

In May 2023, the Goondiwindi Council embarked on a groundbreaking project at the rural town in South Queensland. It signed a 20-year agreement with the private company Hydrogen Collective (H2C) for a $15AU million hydrogen plant, marking another world-leading initiative. This project will utilise recycled wastewater as the feedstock for water electrolysis, making it one of the first commercial hydrogen facilities to use a wastewater feedstock, and will lay out a new commercial model for green hydrogen production. Construction began in July 2023 and the site is expected to become operational later this year.

The Goondiwindi Hydrogen Project is projected to produce approximately 1,350 tonnes of hydrogen gas (H2) annually. The majority is set to be sold by H2C to regional end-users, primarily in the agricultural sector, with supply agreements with other businesses and governments likely further down the pipeline. This initiative will mark the first regional hydrogen sales in Australia, establishing a novel model for local communities to generate and utilise their own energy. It is also anticipated to stimulate job creation and boost the local economy.

While hydrogen is the primary output of this project, the electrolytic oxygen by-product holds

substantial value. By embracing the synergies between hydrogen generation and wastewater treatment, the oxygen by-product will be repurposed for the Goondiwindi WWTP's aeration process. Due to the high purity of the electrolytic oxygen (at 99.98% pure), plant capacity and operating efficiency can be significantly improved, reducing the utility’s dependence on capex-heavy upgrades in the future. The Goondiwindi site will be one of the first in the world to use electrolytic oxygen, potentially setting a new model for developing an on-site source of pure oxygen.

[Source: Shutterstock; audioundwerbung]

- This article has been produced by our knowledge partner, GWI.

- Circular economy sludge biorefineries

- Biomethane bioup collaboration

- Europe biomethane decarbonisation

- Hydrogen and graphite recovered from wastewater in Australia

GWI Links

- Australian business shifts energy-water mix with wastewater-to-hydrogen breakthrough

- Sewage sludge biorefineries: a future for biosolids disposal

- Pressure for methane mitigation methods highlights a myriad of tech solutions

Share your water technology stories with us

Do you have an innovation, research results or an other interesting topic you would like to share with the international water technology industry? The Aquatech website and social media channels are a great platform to showcase your stories!

Please contact our Sr Brand Marketing Manager Annelie Koomen.

Are you an Aquatech exhibitor?

Make sure you add your latest press releases to your Company Profile in the Exhibitor Portal for free exposure.

We promise never to send you spam and you can unsubscribe at any time!